- Metrology - Laboratory

- Laboratory Equipment

- Muffle oven

- SECO/WARWICK S.A.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

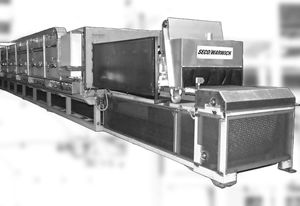

Muffle furnace CABtunnelbrazingelectric

Add to favorites

Compare this product

Characteristics

- Configuration

- muffle, tunnel

- Function

- brazing

- Heat source

- electric, gas

- Atmosphere

- controlled atmosphere

- Other characteristics

- continuous, automatic, horizontal, custom, laboratory, for aluminum

- Maximum temperature

600 °C

(1,112 °F)

Description

Controlled atmosphere brazing of aluminum (CAB), using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers. Since entering this field in 1983,

SECO/WARWICK has led the development of advanced technology in the continuous flow brazing process. Capitalizing on over 100 years of furnace design experience, SECO/WARWICK has driven

innovations such as:

Improved muffle design

Convection heating technology

Continuous atmosphere control systems ACCUBRAZE® PC/PLC controls

Prioritized heating control systems including sinuous loop and gas fired systems

Energy saving designs

System rebuilds and upgrades

Feasibility studies

Catalogs

Other SECO/WARWICK S.A. products

CAB Controlled Atmosphere Brazing Furnaces

Related Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- SECO/WARWICK horizontal oven

- SECO/WARWICK quenching oven

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.