- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Muffle furnace Active Only CABbrazingelectricgas

Add to favorites

Compare this product

Characteristics

- Configuration

- muffle

- Function

- brazing

- Heat source

- electric, gas

- Atmosphere

- controlled atmosphere

- Other characteristics

- automatic, horizontal, for aluminum

- Maximum temperature

600 °C

(1,112 °F)

Description

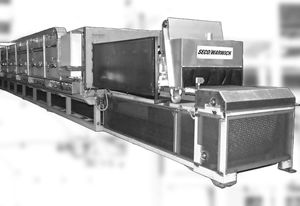

This semi-continuous system allows for variable heating and cooling rates, depending on indexing times. This furnace can braze the widest variety of heat exchangers when lower total production requirements are needed.

Our Active Only® Convection CAB furnaces are based on a multi-step indexing cycle. The product runs in a horizontal position with an infinitely adjustable dwell time based on the hearth load and load configuration. The load thermocouples are predicting the actual temperature of the product. It allows for automatic control of the required heating time for different types of the heat exchangers. The furnace ensures a uniform preheat of product through a patented convection muffle configuration.

The Vertical Brazing CAB furnace is a uniquely designed version of an Active Only® indexing furnace where the brazed elements are positioned horizontally. For some types of heat exchangers such orientation provides benefits as the cladding melts. Vertical positioning of the heat exchanger allows the joints to be evenly filled on a horizontal plane, preventing the brazing alloy from accumulating on one side of the heat exchanger.

Additionally, the furnaces in semi-continuous configuration also are using a vacuum purging. This solution limits the nitrogen consumption and improves furnace-atmosphere cleanliness. Due to vacuum flushing in the furnace vestibule, air is removed not only in the chamber but also from the internal openings of the heat exchanger. Furnaces of this type may be used in the production of some types of heat exchangers (such as PLATE & BAR), which previously required a more expensive technology of brazing in vacuum furnaces.

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK S.A.‘s catalogsOther SECO/WARWICK S.A. products

CAB Controlled Atmosphere Brazing Furnaces

Related Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- Baking oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.