- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

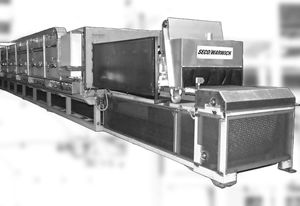

Muffle furnace Continuous CABtunnelbrazingelectric

Add to favorites

Compare this product

Characteristics

- Configuration

- muffle, tunnel

- Function

- brazing

- Heat source

- electric, gas

- Atmosphere

- controlled atmosphere

- Other characteristics

- continuous, automatic, horizontal, high-productivity, for aluminum

- Maximum temperature

600 °C

(1,112 °F)

Description

Our continuous CAB furnaces:

A radiation braze CAB furnace is ideal for brazing similar-size products in a continuous flow environment. This furnace uses a heated muffle to braze the product with high overall efficiency. Our design includes proportionally controlled electric heating or natural-gas-fired combustion. Temperatures are controlled uniformly throughout the length of the furnace by several independently heated zones. These units have a low investment cost and are very efficient with nitrogen atmosphere consumption and require less maintenance compared to the other CAB methods.

Combination convection preheating and radiation brazing furnace systems improve the furnace’s flexibility to run product of different mass and dimension in the same cycle. This type of system is more forgiving when running production intermittently. The initial heat zone uses both convection and radiation heat for uniform preheating. Then in the radiation brazing section the product is brought up to and held at a final uniform temperature to allow the clad materials to melt and form a joint. These units have a medium investment cost and they provide faster processing in a smaller footprint.

A pure convection heat-controlled atmosphere furnace provides processing of the widest variety of products in the shortest cycle time. Convection heat transfer is used to bring the entire part to brazing temperature and maintain temperature uniformity at ± 3 degrees C. using a recirculated nitrogen atmosphere.

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK S.A.‘s catalogsOther SECO/WARWICK S.A. products

CAB Controlled Atmosphere Brazing Furnaces

Related Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- Baking oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.