- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

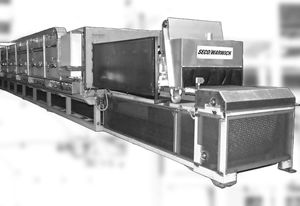

Muffle furnace CABcabinetconveyorroller

Add to favorites

Compare this product

Characteristics

- Configuration

- muffle, cabinet, conveyor, roller

- Function

- brazing

- Heat source

- electric, gas

- Atmosphere

- controlled atmosphere

- Other characteristics

- continuous, high-temperature, automatic, horizontal, vertical, for aluminum

- Maximum temperature

600 °C

(1,112 °F)

Description

SECO/WARWICK provides field technical support and replacement parts for all equipment manufactured inhous. SECO/WARWICK has successfully provided both parts and rebuild services for other manufacturers as well. Technicians are available for equipment breakdowns, rebuilds, upgrades, relocating equipment, troubleshooting, and preventative maintenance.

SECO/WARWICK specializes in providing furnace parts of all types including:

/ heating elements

/ elements of ceramic insulation

/ gas heating system components

/ fan assemblies

/ thermocouples

/ muffles

/ conveyor belts

/ oxygen analyzers

/ fluxer parts: nozzles, pumps, flow meters, filters

/ electrical systems parts: frequency inverters,

/ thyristor controllers, PLC

/ complete sets of maintenance parts

SECO/WARWICK has the knowledge and experience to provide repairs and upgrading of a CAB equipment, whether it was produced by SECO/WARWICK or other manufacturers:

/ increasing the capacity of the CAB continuous lines with the addition of a Convection Preheat Chamber,

/ replace water cooled chambers with an air jacket solution,

/ replace fiber glass curtains by the strip foil,

/ upgrading dated control systems with the latest technology,

/ update the gas heating system following to meet current safety standards,

Our service team is to your disposal offering a wide range of services:

/ annual maintenance and overhaul of the equipment,

/ heating uniformity test using a data logger,

/ checking the brazing equipment tightness using Helium detection method,

/ technical support solving other problems CAB equipment and process

Catalogs

Other SECO/WARWICK S.A. products

CAB Controlled Atmosphere Brazing Furnaces

Related Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- Baking oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.