- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Chamber furnace VABbrazingvacuumcontinuous

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- brazing

- Atmosphere

- vacuum

- Other characteristics

- continuous, batch, high-volume, for aluminum

Description

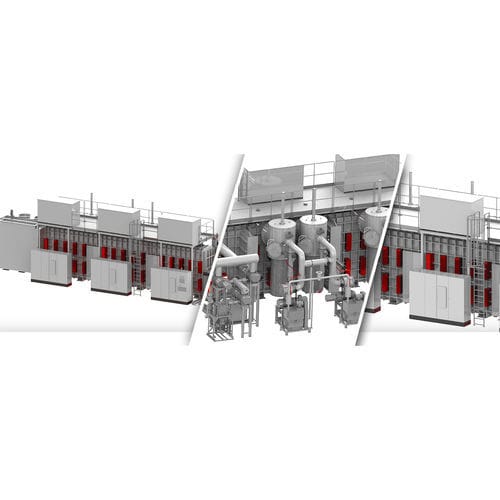

VAB Multi-Chamber Modular Furnace

The VAB multi-chamber furnace is a modular unit designed to be customized to meet the specific requirements of the customer, particularly for high-volume, high-capacity production. The underlying concept of the process, which utilizes no flux (no flux technology) and significantly enhances environmental safety, mirrors that of a chamber furnace. However, the multiplication of chambers allows for a substantial increase in capacity, achieved, for example, by incorporating additional heating or post-cooling chambers, resulting in time savings.

Features:

/ Standard horizontal capacity of 1400 kg and more,

/ Operating temperature: – 650°C,

/ Temperature uniformity: +/-3°C,

/ Uniform and efficient radiation heating,

/ Partial pressure control,

/ High vacuum processing up to 10-5 mbar,

/ Cooling gases: N2,

/ Metal rectangular heating zone/ Computerized control system (PLC+IPC), operator-friendly,

/ Compliance with global industry standards,

/ Horizontal orientation,

/ Metal rectangular heating zone.

Vacuum fluxless brazing offers the advantages of eliminating flux inclusions and designing blind cavities, winding paths, and small transitions in brazed parts without the detrimental effects associated with flux removal and trapping after brazing. Precise temperature control makes it possible to leverage the narrow soldering temperature range available for this type of material, achieving excellent solder joints. The blast furnace is additionally an all-in-one device capable of employing multiple solutions (de-oiling, preheating, brazing, sub-cooling, cooling, and sub-cooling).

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK S.A.‘s catalogsRelated Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- Baking oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.