- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

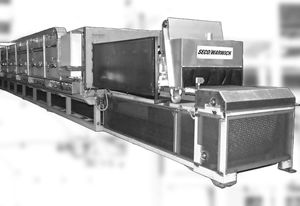

Chamber furnace CuproBraze® brazingelectricgas

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- brazing

- Heat source

- electric, gas

- Atmosphere

- nitrogen

- Other characteristics

- automatic, horizontal, compact, for copper

- Maximum temperature

670 °C

(1,238 °F)

Description

The CuproBraze process is a brazing process specifically developed for the manufacturing of automotive and heavy-duty industrial heat exchangers. By using high strength copper alloys it is possible to manu-facture light, strong, efficient and compact heat exchangers at a low cost with this envi-ronmentally friendly, lead-free process. The brazing of CwproBraze* radiators uses a non-toxic low temperature melting alloy that works well in a nitrogen based controlled atmosphere furnace. The brazing material is lead free and there is no post-braze treatment

required, such as rinsing. Binders and braze alloys can be applied to the tubes, fin tips or

headers by spraying, brushing or rolling. After brazing, the brazed copper-brass joints are

significantly stronger than the solder metal and do not suffer from galvanic corrosion.

Developed for this process, anneal resistant header, fin and tube materials assure the

strength of the products.

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK S.A.‘s catalogsOther SECO/WARWICK S.A. products

CAB Controlled Atmosphere Brazing Furnaces

Related Searches

- SECO/WARWICK oven

- SECO/WARWICK chamber oven

- SECO/WARWICK electric oven

- SECO/WARWICK heat treatment oven

- SECO/WARWICK laboratory oven

- SECO/WARWICK combustion oven

- SECO/WARWICK gas oven

- SECO/WARWICK tunnel oven

- Baking oven

- SECO/WARWICK industrial oven

- SECO/WARWICK high-temperature oven

- SECO/WARWICK controlled atmosphere oven

- SECO/WARWICK automatic oven

- SECO/WARWICK vacuum oven

- SECO/WARWICK continuous oven

- SECO/WARWICK annealing oven

- Forced convection furnace

- SECO/WARWICK programmable oven

- SECO/WARWICK melting oven

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.