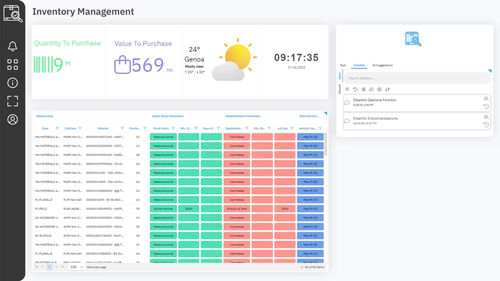

Inventory management software order managementprocurement managementindustrial

Add to favorites

Compare this product

Characteristics

- Function

- order management, procurement management, inventory management

- Applications

- industrial, for production

- Other characteristics

- high-performance

Description

Optimize stock levels in the logistical - distribution chain

For companies, Inventory management, or stock management, is a key element to optimize the logistics service level and meet customer expectations. For this reason, within the logistics-distribution chain, stock management must include solid inventory planning.

The definition of an infinite capacity replenishment plan is achieved through the analysis of some factors:

| Sales forecasts and their reliability

| Target service level

| Orders

| Stocks

| Replenishments

Main features of inventory management software

In order to manage the inventory and to optimize the stock, vendor management inventory is handled directly by the company:

| Plans monthly target stock profiles, finding the best trade-off between service level, coverage depth and inventory management costs.

| Configures different coverage policies at different product/market aggregation levels and calculates target stock for every logical node in the logistics network

| Generates a Master Production Schedule by conciliating monthly strategic targets with real stock availability according to a set of inventory policies

| Calculates the replenishment plan for every logical node in the logistics network and allows top-down and bottom-up analysis of stock coverage, replenishment and trends

| Forces service levels, safety stock, target stock and replenishment values

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.