- Packing - Handling - Logistics

- Packing and Packaging

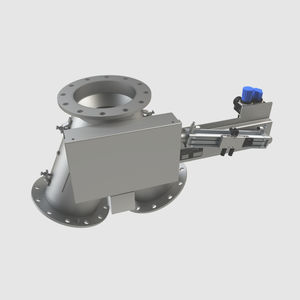

- Vertical bagging machine

- Segler-Förderanlagen Maschinenfabrik GmbH

Vertical bagging machine weightfor bulk materialsflexible

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- weight

- Product applications

- for bulk materials

- Other characteristics

- flexible

Description

The highest requirements for the quality and reproducibility of products require the precise and punctual coordination of accurate production processes.

Only minimal tolerances are allowed, which, for media with difficult properties with regard to grain size, flow behavior, consistency, and bulk weight, requires precision work where design and process technology are concerned. When raw materials, aggregates etc. are added to the processing chain or when products from the process are to be filled into receptacles such as sacks, tanks etc., a wide range of challenges need to be solved. Examples of this include media that has clumped together in storage, dust formation, ensuring exact/calibrated quantities etc.

Product range

■Hopper with sack support

■Integrated sack emptying

■Extraction with filter system

■Discharge & metering augers

Properties/variants

Configurations Screens, filters, dispersing agitators, tools adapted to the product, such as single-shaft/multiple-shaft augers; hoppers with sack support, fill level probes, vibration motors, screen units, magnetic separator, dust extraction, housing with dust-tight flaps

VariantsStationary or mobile, dust-proof, gas-tight, food safe, ATEX-compliant

SealsProduct-specific seals

Advantages

■Exact metering and handling even for extremely hard-to-handle materials

■Flexible system configuration

■Variable adaptation of products and services

■Also for the metering and handling of multiple components

■Easy to clean

■Variable feed hopper sizes

Catalogs

No catalogs are available for this product.

See all of Segler-Förderanlagen Maschinenfabrik GmbH‘s catalogsOther Segler-Förderanlagen Maschinenfabrik GmbH products

Metering & handling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.