- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Radiant burner

- SELAS HEAT TECHNOLOGY LLC

Radiant burner Kgasdirect firedheating

Add to favorites

Compare this product

Characteristics

- Type

- radiant

- Power source

- gas

- Firing

- direct fired

- Applications

- heating

- Head length

- standard

- Other characteristics

- modular, infrared

- Power

8,000 BTU/h

Description

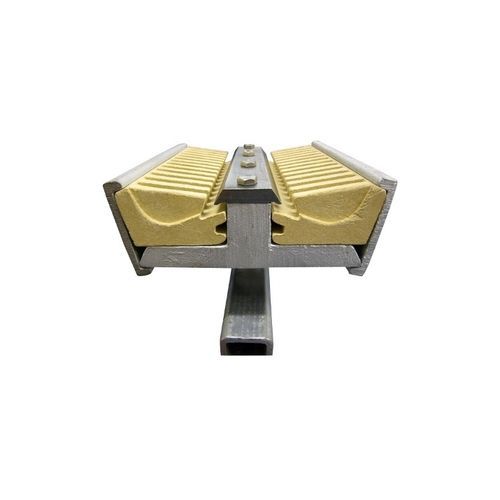

The Model K Series is available in a 7-inch size with either cast iron or special alloy components and employs an air-gas mixture impinging directly on the finned refractory surface to produce a high-density flux of maximum radiance. The flame itself is not the source of infrared radiation. Its function is to heat the refractory to temperatures of 1650° to 2000°F. The refractory then emits infrared energy in the micron range most efficient for the product heating process.

Performance

Develops Radiant Temperatures to 2000° F with Turndown Ratio of 4 to 1

Design

Modular burner sections with KN-Standard size of 7″ in length

Durable Construction with cast iron components (CI-KN)

High Temperature versions also (KN-SS-SC)

Features and Benefits

Finned cordierite ceramic refractory emitters

30% IR, 70% convective energy output

Stainless steel spacer to deliver combustion mixture

Machined, grey iron sand cast body

High temperature, corrosion resistant alloy side plates lifetimes

Machined, grey iron sand cast body continuously operating ovens

Modular burner sections with carbon steel unions

Replaceable emitter with secure attachments

Radiant heat is distributed uniformly

High velocity radiant heat diffuses surface boundary layers

No ported holes to clog, fewer dark spots

Longer wear resistance than cast iron baffle

Less warping, longer burner lifetimes

Structural integrity in continuously operating ovens

Easy and quick replacement of burner sections

Designed to reduce maintenance costs

Catalogs

Rotary Retorts

8 Pages

Rotary Retorts

2 Pages

Related Searches

- Gas burner

- Direct fired burner

- Natural gas burner

- Nozzle mix burner

- Indirectly fired burner

- Heaters burner

- Fuel oil burner

- Standard burner

- Pilot burner

- Furnace burner

- Infrared burner

- Radiant burner

- Modular burner

- Food burner

- Premix burner

- Hot air burner

- Atmospheric burner

- Flange burner

- Chamber burner

- Air heating burner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.