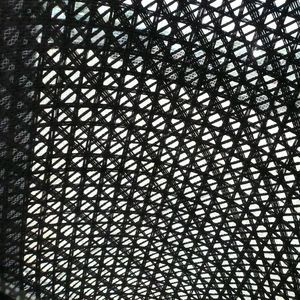

Carbon fiber CBX seriesfabriccut

Add to favorites

Compare this product

Characteristics

- Material

- carbon

- Form

- fabric

- Technical characteristics

- cut

Description

Biaxial Non Crimp Fabrics (NCF) in carbon fiber, are made up of layers with parallel fibres laid in 2 orientations, stitched with texturized polyester yarn. The most commonly used Biaxial Non Crimp Fabrics (NCF) in carbon fiber are oriented at ±45º or 0º90º. It’s also possible to have ±30º or ±60º on request. The longitudinal direction of 0° is always the direction of the length of the roll and the stitching direction. It’s also possible, for special requests, to combine the orientation. (i.e. +45º90º or 0º-45º etc.)

Biaxial Non Crimp Fabrics (NCF) in carbon fiber are produced in a standard width from 1270mm to 2540 mm and, or they can be cut in tapes without the fibres fall apart. Currently the know-how developed over the years has allowed the production of a range of Non Crimp Fabrics ranging from 50 gr / M² to 1200 gr / M².

Resin Compatibility

Carbon fibers used for the production of our multiaxial – non crimp fabrics are coated with a broad range of sizing to provide compatibility with multiple resin systems.

Selcom Multiaxial – Non Crimp Fabrics (NCFs) are manufacured to meet the individual needs of our customers. All the fabrics can be based on the final application in order to deliver the expected performance.

Fiber orientation

Selcom Multiaxial – Non Crimp Fabrics (NCFs) are made up of layers with parallel fibres laid in different orientations, stitched with texturized polyester yarn.

The most commonly used Multiaxial - Non Crimp Fabrics (NCF) are oriented at ±45º or 0º90º,but it’s also possible to have ±30º or ±60º on request. The longitudinal direction of 0° is always the direction of the length of the roll and the stitching direction.

Catalogs

No catalogs are available for this product.

See all of SELCOM SRL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.