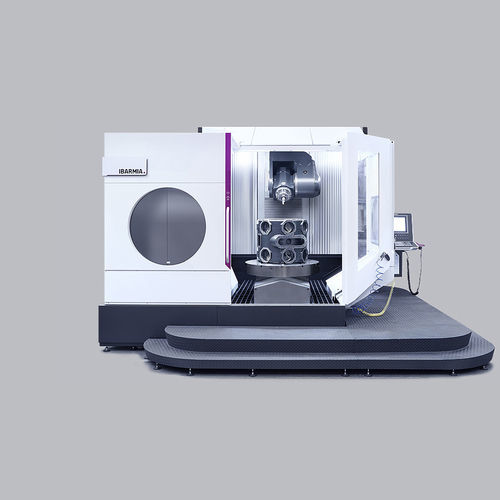

The T SERIES is designed for high productivity of heavy pieces thanks to its high load capacity rotary tables and powerful spindles. Its award-winning tilting heads provide the speed,

accuracy and reliability required for the most complex jobs.

The most advanced automation solutions for automatic pallet changing and special head changing operations, make the T SERIES the ideal solution for the most demanding production

requirements. The MULTIPROCESS models integrate milling, turning anf grinding capacity, reducing the number of machines required to produce a wide range of pieces.

The T SERIES is the ideal solution for high production of medium and large size cubic pieces in a single set up, with power and accuracy. A generous workspace and the combination of linear and rotary axes, offer a wide range of solutions for advanced machining in 5 axes / 5 faces on

parts up to ø3600 mm and h2150 mm in a wide range materials and the most complex geometries.