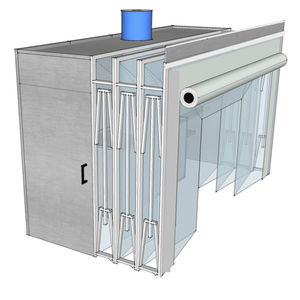

Enclosed paint booth RETRA-FLEX PLfor heavy trucks

Add to favorites

Compare this product

Characteristics

- Structure

- enclosed

- Applications

- for heavy trucks

Description

The side walls are made of 1 mm galvanized sheet metal, with 40 mm glass wool insulation. In order to provide an ergonomic view and a longer service life, the outer surface of the panels is painted with imported static powder paint. Our products have the lighting system that has been designed to optimize color control during the painting phase.

In the paint booth, there is a suspension system with rails hanging from the ceiling, which makes it possible to paint parts next to the automobile. The ceiling is the section that ensures the homogeneous flow of air coming from the heat exchanger, through the plenum and the filters.

The ceiling consists of sheet metal panels with a special insulating backing, and in order to clean the air supplied to the cabin, a filter element made of non-flammable, special high-performance, long-life material is placed under the ceiling. There is a 4-leaf door at the front, and 1 entry and exit door system for operators. Door items have viewing windows made of safety glasses. The thickness of the doors is 55 mm and insulated with 55 mm glass wool. All windows include glasses.

Make-up Air Unit: This unit supplies fresh filtered air to the booth and blows used air upside down while painting. On the other hand, during drying, it heats the air up to 60 °C and supplies the cabin, mixes the used air with fresh air at the rate of 10% (through the multi-register) and circulates it after heating.

Air heating is provided by a diesel or oil burner with a capacity of 150,000 kcal / h and a heat exchanger made of 304 quality stainless steel sheet.

VIDEO

Related Searches

- Spray booth

- Blast room

- Filter spray booth

- Enclosed spray booth

- Vehicle spray booth

- Open spray booth

- Pressure blast room

- Part spray booth

- Powder coating booth

- Automatic blast room

- Dry filter spray booth

- Filter powder coating booth

- Blast cabinet for the automotive industry

- Automatic spray booth

- Automatic powder coating booth

- Ventilated spray booth

- Part powder coating booth

- ATEX spray booth

- Paint booth with drying

- Paint booth with horizontal ventilation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.