Flexible conveyor belt Metalcordrubbermetalindustrial

Add to favorites

Compare this product

Characteristics

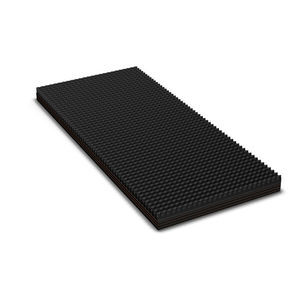

- Type

- flexible

- Material

- rubber, metal

- Sector

- industrial, for the mining industry, for the recycling industry

- Tolerance

- high-resistance, abrasion-resistant, heat-resistant, oil-resistant, fire-resistant, cold-resistant

- Other characteristics

- heavy-duty, reinforced

Description

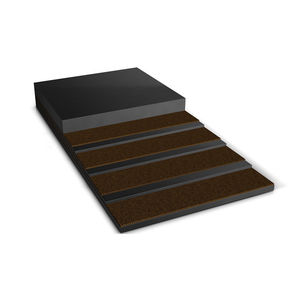

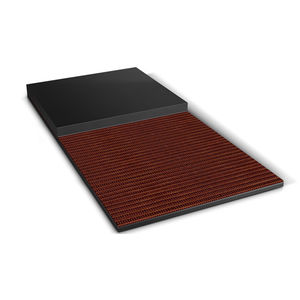

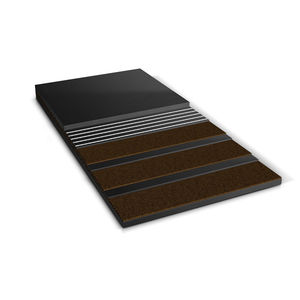

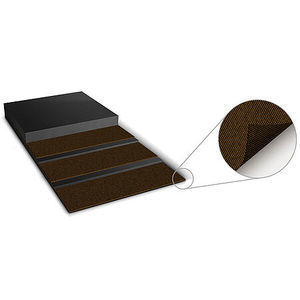

Outstanding impact and cutting resistance: a unique and unrivalled steel carcass construction

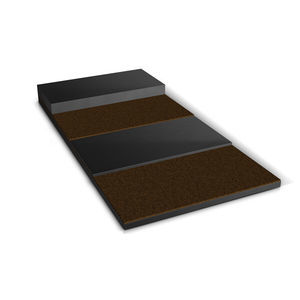

The Metalcord belt features a special structure, boasting a carcass with three layers (1 warp, 2 wefts), resistant to the toughest tear and cut issues (100% metal carcass).

- Carcass construction of three layers of rubber embedded cords

- Two different constructions are available:

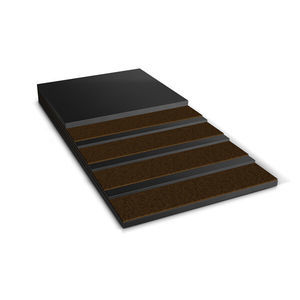

- Metalcord belts with M-cords in the warp direction offer the highest elasticity for applications with tight curves or small pulley diameters

- Metalcord belts with E-cords in the warp direction provide low elongation for applications with long centre distances

- Compliant with ISO 15236

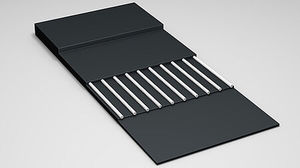

- Excellent cord/rubber adhesion even under tough working conditions

- Exceptional resistance to repeated impact

- Outstanding resistance to penetration limiting longitudinal cuts and tears

- Weft cords included in the carcass increase service life since the full cover thickness can be used

- The option to use mechanical fasteners for emergency situations and fast repairs

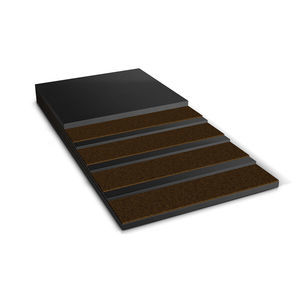

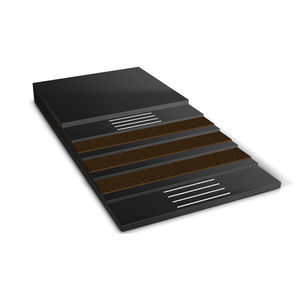

- The Metalcord construction with the highly elastic M warp cords (4x7 design) offers a low elastic modulus and strong impact resistance. It combines the advantages of steel carcasses with the superior impact resistance of textile belts and is particularly suitable for:

- Installations with repeated impacts and a high risk of cuts and tears

- Small pulley diameters

- Very small radii for horizontal and vertical curves

- The option to use crowned pulleys for centring on short conveyors

- Replacing textile belts by steel carcass constructions without any significant change in the conveyor system

Related Searches

- Conveying belt

- Plastic conveyor belt

- Industrial conveyor belt

- PP conveyor belt

- Process conveyor belt

- Flexible conveyor belt

- Metal conveyor belt

- High-resistance conveyor belt

- Rubber conveyor belt

- Textile conveyor belt

- PA conveyor belt

- Conveyor belt for the chemical industry

- Heavy-duty conveyor belt

- Smooth conveyor belt

- Abrasion-resistant conveyor belt

- Heat-resistant conveyor belt

- Polyester conveyor belt

- Oil-resistant conveyor belt

- Conveyor belt for the mining industry

- Conveyor belt for the recycling industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.