Scanning Speed: ≤3280′ /s

Scanning Repeat Positioning Accuracy: ±5μm

Laser high-speed micro-machining is one of the indispensable, and widely used laser methods in micro-holes processing. With the reduction of the thickness of target material, and the increase of hole matrix density, the traditional machining and galvanometer scanning cannot reach the expected speed and accuracy. Compared with the conventional galvanometer scanning device, high-speed polygon mirror scanning with nanosecond high repetition rate laser can effectively realize high-speed laser precision micro-hole arrays and solve the research projects in great demand.

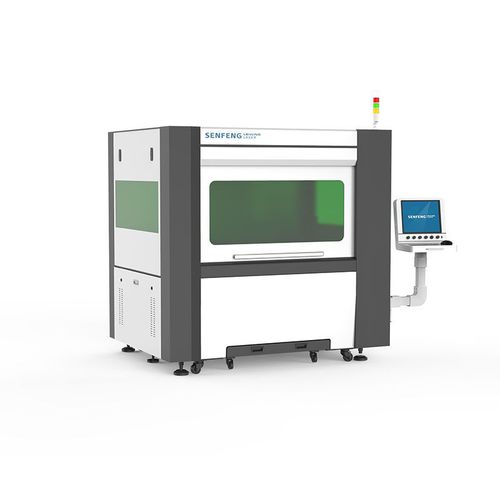

TECHNICAL PARAMETERS

Machine Size: 82.2″*71.6″*78.7″

Workbench Size: 15.74″*15.74″

Laser Power(w): 500

Laser Wavelength(nm): 1064

Laser Pulse Width(ns): 30/60/120/240

Laser Frequency(kHz): 2000/1000/500/500

Diameter of Focused Spot(μm): ≤40

Effective Focal Length: 16.53″

Scanning Range: 11.8″*11.8″

Scanning Speed: ≤2000’/s

Scanning Line Frequency(Hz): 1600

Scanning Repeat Positioning Accuracy(μm): ±5μm

Processing Methods: Linear mode, dot matrix mode, bmp mode

Positioning Method: Polygon mirror scanner is matched with mechanical shaft

PROCESSING METHODS

Laser lattice scanning

Laser linear scanning

High-speed BMP bitmap processing

Laser drilling

Laser linear cutting

High density micro-hole array processing

laser beam grooving