- Production Machines

- Forming Machine

- Seny S.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

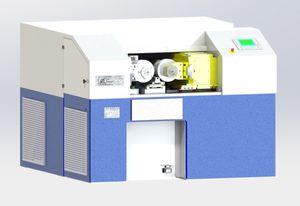

Rolling mill

Add to favorites

Compare this product

Description

TOOTHED RACK rolling mills

Combining the laminate with the CNC control the advance and the use of reversible rolling rod is an innovation that allows chipless manufacturing a wide variety of profiles splined shaft, involute profiles (FROM 5480 and DIN 5481) and special profiles with an accuracy hitherto unknown. Forces the use of very small and very accurately adjustable shaping expands its scope to the hollow shafts and other works of complex formed.

The machines of the series RACK used to cold form, chipless and economically toothed external, splined shaft profiles and profiles involute (FROM 5480 and DIN 5481). For example in shafts, drive shafts, axes removable (also hollow shafts), etc. It can also be made more tooth positioned relative to each other. According to the machine model, with a single clamping operation can be made 10 different profiles. Implementation and provision of tools is optimized for shaping, which improves implementation contour, which can be carried out more easily and economically than with other known manufacturing methods. At the same time greater flexibility is achieved in production.

Tools execute a vertical translation movement in opposite directions. This translational movement overlaps the carriage traverse horizontally. All axes have CNC control, so the degree of deformation can be individually adjusted to each workpiece. In each working step can be programmed to 15 different progress. In this way, manufacture by the forming process may employ various materials with high precision and minimum forming force (for instance, for hollow parts) considering different deformation characteristics and, Besides, protecting tools.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.