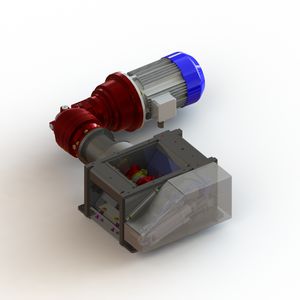

Rotor mill production line Broyeur SFH 600 -EPEhorizontalfor metalsautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- rotor

- Orientation

- horizontal

- Product applications

- for metals

- Other characteristics

- automatic

- Output

Min.: 50 kg/h

(110 lb/h)Max.: 900 kg/h

(1,984 lb/h)

Description

The advantages of breaking-up ferrous or non-ferrous chips

A higher market value for your shredded chips for their reclamation in recycling channel thanks to chips densification.

Volume reduction, therefore limited CO2 emissions (fewer trucks and reduced transport costs).

Calibration with Hardox screen plates or rotating sieves (specific grain size guaranteed).

Productivity and performance contract overtime.

Environmental requirements compliance and increased workers safety..

The horizontal chip crushers are design to reduce long chips and balls and eject metal and foreign parts.

Crushing is often a necessary phase to ensure the performances and the lifetime of the chips disposal systems, especially before centrifuging /drying or before compacting /briquetting.

Operation

The SFH crushers are equipped of removable hardened teeth and knifes arranged on one or double-shaft. The assembly is drive by an angular and double global motor reducer for decrease the speed and increase the torque. On the crusher’s frame, the combs are fixed for cut the chips during the rotation of the multiple-teeth. In the lower parts, Hardox grids with various holes diameter are installed below the rotor to obtain the required quality size.

Catalogs

No catalogs are available for this product.

See all of SFH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.