- Production Machines

- Other Manufacturing Equipment

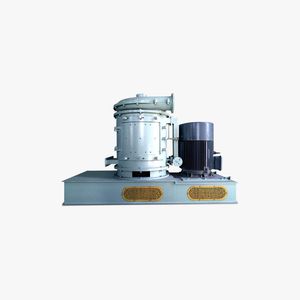

- Jet mill

- Shandong ALPA Powder Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fluidized bed jet mill MQW seriesfor rubberfoodchip

Add to favorites

Compare this product

Characteristics

- Technology

- fluidized bed jet

- Product applications

- for rubber, food, chip, for lithium battery, for powders, kaolin, for paper, mica, graphite, sulfur, potassium manganate, silica, quartz, silicon, for wood, talc

- Other characteristics

- laboratory, dry milling, high-speed, ultrafine, micronization, air classifier, high-pressure

- Sector

- for the pharmaceutical industry, for recycling, for the plastics industry, for the chemical industry

- Final grain size

Max.: 45 µm

Min.: 3 µm

- Output

Max.: 12,000,000 g/h

(26,455 lb/h)Min.: 300 g/h

Description

Suitable for grinding materials with high hardness, high purity and high added value.

Low-temperature pulverization without medium, especially suitable for heat-sensitive, low-melting materials.

Control particle sizes precisely, available particle size D50:1~25μm.

Grinding in a complete closed system, no dust, low noise, clean and environmentally friendly.

Working Principle

Fluidized Bed Opposed Air Jet Mill: After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure airflows, the materials are repeatedly collided, rubbed, and sheared to be crushed. The crushed materials rise with the suction of the fan. The airflow moves to the classification zone. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the classification wheel for collection, and the coarse particles descend to the crushing zone and continue to be crushed.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shandong ALPA Powder Technology Co., Ltd.‘s catalogsOther Shandong ALPA Powder Technology Co., Ltd. products

Dry Grinding

Related Searches

- ALPA mill

- Horizontal grinding mill

- Vertical grinding mill

- ALPA food mill

- Rotor lump breaker

- Impact grinding mill

- ALPA waste mill

- Roller grinding mill

- ALPA plastic mill

- Hammer grinding mill

- ALPA mill for the pharmaceutical industry

- Grinding mill for the food industry

- ALPA recycling mill

- ALPA laboratory mill

- Stainless steel grinding mill

- Compact grinding mill

- ALPA mineral mill

- Powder grinding mill

- ALPA dry milling mill

- Rotary drum grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.