- Production Machines

- Other Manufacturing Equipment

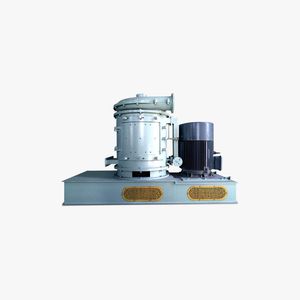

- Hammer mill

- Shandong ALPA Powder Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Hammer mill CUM seriesfor rubberfoodchip

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Product applications

- for rubber, food, chip, for lithium battery, potassium manganate, mica, graphite, silica, quartz, talc, silicon, kaolin, sulfur

- Other characteristics

- laboratory, compact, high-speed, static

- Sector

- for the pharmaceutical industry, for recycling, for sample preparation, for the plastics industry, for the chemical industry

- Rotational speed

5,550 rpm, 7,500 rpm, 12,000 rpm

(34,872 rad.min-1, 47,124 rad.min-1, 75,398 rad.min-1)- Output

Max.: 500 kg/h

(1,102 lb/h)Min.: 5 kg/h

(11 lb/h)- Motor power

Max.: 15 kW

(20.39 hp)Min.: 3 kW

(4.08 hp)

Description

Tooth claws, movable hammers, hammers, and grinding discs are easy to replace.

It is widely used in chemical industry, inorganic salt, medicine, food, pigment, dye, pesticide, battery material, mineral, refractory material and other industries.

Working Principle & Advantages

The material is evenly sent to the grinding chamber by the feeding system, and receives the strong impact of the high-speed rotating grinding movable disk. At the same time, it receives the action of multiple comprehensive forces such as friction, shear, and collision between the static disk and the gear ring, so that the grinding, according to the nature of the material, the grinding movable disk and the static disk can be combined with different structures to meet the grinding needs of different materials.

Particle size range D50: 10~850μm;

The aperture of the screen is 2mm-3mm;

Compact structure, small footprint, easy to disassemble and clean;

The entire system is sealed and ground, with less dust, low noise, and the production process is clean and environmentally friendly;

The control system adopts program control, which is easy to operate;

Low installed power, wide application range and high cost performance;

Different installation combinations are suitable for different process requirements;

The motor can be connected with a belt to increase the speed, breaking through the problem that well-known motor brands do not have high-speed motors;

Explosion-proof design can be selected to meet the ultra-fine grinding processing requirements of flammable, explosive and oxidizing materials;

Catalogs

No catalogs are available for this product.

See all of Shandong ALPA Powder Technology Co., Ltd.‘s catalogsOther Shandong ALPA Powder Technology Co., Ltd. products

Dry Grinding

Related Searches

- ALPA mill

- Horizontal grinding mill

- Vertical grinding mill

- ALPA food mill

- Rotor lump breaker

- Impact grinding mill

- ALPA waste mill

- Roller grinding mill

- ALPA plastic mill

- Hammer grinding mill

- ALPA mill for the pharmaceutical industry

- Grinding mill for the food industry

- ALPA recycling mill

- ALPA laboratory mill

- Stainless steel grinding mill

- Compact grinding mill

- ALPA mineral mill

- Powder grinding mill

- ALPA dry milling mill

- Rotary drum grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.