- Production Machines

- Other Manufacturing Equipment

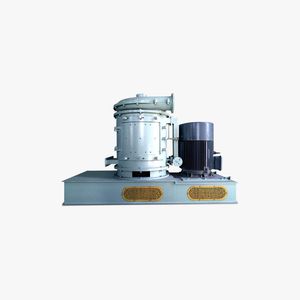

- Roller mill

- Shandong ALPA Powder Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Roller mill RLM seriesverticalfor rubberfood

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Orientation

- vertical

- Product applications

- for rubber, food, chip, for lithium battery, mica, graphite, silica, quartz, silicon, kaolin, potassium manganate, sulfur, talc

- Material of the grinding tool

- stainless steel

- Other characteristics

- laboratory, ultrafine

- Sector

- for the pharmaceutical industry, for recycling, for the plastics industry, for the chemical industry

- Output

Min.: 600 kg/h

(1,323 lb/h)Max.: 5,000 kg/h

(11,023 lb/h)- Motor power

152 kW, 237 kW

(206.66 hp, 322.23 hp)

Description

Large output and high production efficiency

Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets of equipment, no large-scale civil engineering, all fine powder can be recycled, no pollution to the environment, and the dust removal effect reaches the dust industry Emission Standards;

Widely used in calcium carbonate (calcite, marble, limestone, chalk), barite, kaolin, dolomite, magnesite, alumina, ultrafine cement, slag, steel slag and other industries;

Particle size range: D50: 1.5~45μm.

Working Principle

The ultra-fine roller mill drives the main shaft to rotate through the transmission device. The upper end of the main shaft is connected to the rotor frame. The frame is equipped with an auxiliary shaft and a grinding wheel is installed on the auxiliary shaft. When the main shaft rotates, the auxiliary shaft rotates with it. The grinding wheel on the auxiliary shaft not only revolves around the main shaft, but also rotates around the respective auxiliary shaft.

The grinding wheel generates strong centrifugal force during the revolution and rotation process, and has a strong roller grinding action with the stator. The ground material is driven by the centrifugal force and the rotating force field of the grinding wheel, and enters the grinding zone composed of the grinding wheel and the stator. The material is ground under the action of squeezing force and grinding force.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shandong ALPA Powder Technology Co., Ltd.‘s catalogsOther Shandong ALPA Powder Technology Co., Ltd. products

Dry Grinding

Related Searches

- ALPA mill

- Horizontal grinding mill

- Vertical grinding mill

- ALPA food mill

- Rotor lump breaker

- Impact grinding mill

- ALPA waste mill

- Roller grinding mill

- ALPA plastic mill

- Hammer grinding mill

- ALPA mill for the pharmaceutical industry

- Grinding mill for the food industry

- ALPA recycling mill

- ALPA laboratory mill

- Stainless steel grinding mill

- Compact grinding mill

- ALPA mineral mill

- Powder grinding mill

- ALPA dry milling mill

- Rotary drum grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.