- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

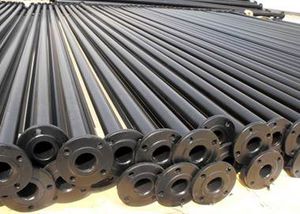

- Water pipe

- Shandong Donghong pipe Industry Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Water pipe steelcompositehigh-pressure

Add to favorites

Compare this product

Characteristics

- Use

- for water

- Material

- steel, composite

- Applications

- high-pressure, construction

- Other characteristics

- standard, chemical-resistant, anti-corrosion, with flange, coated

- Inner diameter

Min.: 40 mm

(1.575 in)Max.: 1,400 mm

(55.118 in)- Pressure

100 bar

(1,450.377 psi)

Description

1. High pressure bearing and good mechanical performance: continue the advantages of steel pipes, have high mechanical strength and have strong bearing capacity for external impacts such as impact bending etc.

2. Strong chemical corrosion resistance: having the advantages of plastic pipes, the plastic coating has strong chemical corrosion resistance. The products can be coated with flanges, and all kinds of pipe fittings are treated with anti-corrosion treatment on inside and outside coatings to ensure the anti-corrosion effect of the whole pipeline.

3. Strong adhesion of coating: pretreatment by special process, reaching Sa2.5 standard before plastic coating, scientific and reasonable technology and advanced production equipment ensure coating quality.

4. No fouling, low fluid resistance: the inner surface coating is precise and non-fouling, thus the friction coefficient and the roughness coefficient are smaller than those of ordinary steel pipes. The roughness coefficient is equal to that of the plastic pipes, i.e. 0.01.

5. Various connection methods, convenient for construction: the products can be connected by various methods, including flange connection, quick coupling connection, bimetallic connection, and butt-welding connection, which is convenient for installation.

6. The internal and external coatings can be coated with different coating materials and colors according to customer requirements: the main coating methods include internal and external polyethylene powder coating, internal and external epoxy resin powder coating, as well as internal polyethylene powder coating and external epoxy resin powder coating

Other Shandong Donghong pipe Industry Co., Ltd products

Composite Pipe System

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.