- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Gas pipe

- Shandong Donghong pipe Industry Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

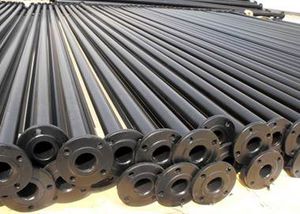

Gas pipe stainless steelfor mining applicationslightweight

Add to favorites

Compare this product

Characteristics

- Use

- for gas

- Material

- stainless steel

- Applications

- for mining applications

- Other characteristics

- lightweight, corrosion-resistant, reinforced, welded, flange, spiral

- Inner diameter

Min.: 300 mm

(11.811 in)Max.: 1,000 mm

(39.37 in)- Outer diameter

Min.: 323 mm

(12.717 in)Max.: 1,020 mm

(40.157 in)- Pressure

0.97 bar

(14.069 psi)

Description

Performance features:

1. Product structure: the reinforced spiral welded stainless steel pipe is a new type of strong corrosion-resistant pipe. The pipe base is made of 304 stainless steel. The stainless steel strip with a certain width is folded and rolled by special pressure roller combination of production equipment and then welded to the pipe.

2. Light weight: compared with other pipes with the same specification and model, this kind of pipes greatly reduces the weight of the pipe, which makes the labor intensity low and the construction efficiency relatively fast;

3. High ring stiffness: produced by 304 stainless steel strip, the pipe will not be deformed or lose stability arising from deformation, which meets the requirements for negative pressure performance of methane gas drainage pipes;

4. Corrosion resistance: the 304 stainless steel strip used for the reinforced spiral welded stainless steel pipes is austenitic stainless steel. This type of stainless steel is the most superior in stainless steels. Thus, the corrosion resistance performance is still superior without any other corrosion resistance measure;

5. Interchangeability of connection methods: the commonly used steel pipes in the market are generally connected by flange connection. The reinforced spiral welded stainless steel pipes also can be connected by clamp connection, achieving the interchangeability between the flange and the quick coupling and thus correspondingly improving the construction efficiency;

6. High weld strength: the pipe weld is carried out by high-quality 304 stainless steel and specially treated wire, thus the weld strength is higher than the ordinary weld strength.

Other Shandong Donghong pipe Industry Co., Ltd products

Composite Pipe System

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.