- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Gas pipe

- Shandong Donghong pipe Industry Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

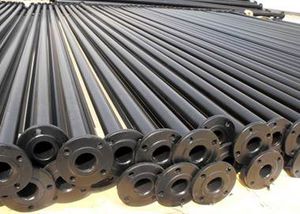

Gas pipe steelgalvanised steelfor mining applications

Add to favorites

Compare this product

Characteristics

- Use

- for gas

- Material

- steel, galvanised steel

- Applications

- for mining applications

- Other characteristics

- standard, lightweight, corrosion-resistant, reinforced, welded, corrugated, spiral

- Inner diameter

Max.: 1,000 mm

(39.37 in)Min.: 300 mm

(11.811 in)- Outer diameter

Max.: 1,020 mm

(40.157 in)Min.: 323 mm

(12.717 in)- Pressure

0.97 bar

(14.069 psi)

Description

Executive standard: GB/T13912-2002 Metallic Coatings — Hot Dip Galvanized Coatings for Steel Parts — Technical Requirements and Test Methods

Performance features:

1. Light weight: compared with other pipes with the same specification and model, the weight is reduced by 70%; the labor intensify is low and the construction efficiency is fast;

2. Corrosion resistance: the spiral welded corrugated galvanized steel pipe is produced by hot-dip galvanizing process. The thickness of zinc layer is higher than the requirements in national standards for the thickness of zinc layer. The corrosion resistance lifetime of the pipeline is long;

3. High ring stiffness: the main requirement of the methane gas drainage pipes is the negative pressure performance. The experimental data shows that the ring stiffness meets SN16;

4. Uniform zinc layer: hot dip galvanized pipes have the uniform thickness of the zinc layer;

5. Strong adhesion: the galvanized steel strip pipes are treated by hot dip galvanizing process. Through the hammering method and the file method, the zinc layer has no peeling;

6. Low noise: since the inner wall of the pipe is smooth with no protrusion, the surface smoothness is high, thus the noise generated by the pipeline during operation is greatly reduced.

Other Shandong Donghong pipe Industry Co., Ltd products

Composite Pipe System

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.