- Building - Construction

- Industrial Building Equipment

- Compressed air aftercooler

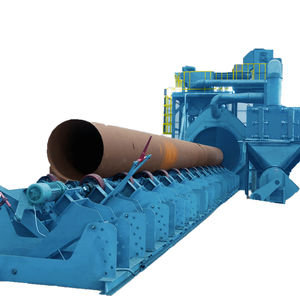

- Shandong Kaitai Shot Blasting Machinery Share Co.,

Compressed air aftercooler ABAC seriesindustrial

Add to favorites

Compare this product

Characteristics

- Material

- compressed air

- Applications

- industrial

Description

Clean, Dry Compressed Air with Airblast Aftercoolers

Compressed-air conditioning is indispensable for ensuring fault-free performance of blasting and paint spraying equipment as well as for compressed air tools

Conditioned compressed air contributes to improving the quality of blasted surfaces since most of the oil and water have been removed from the compressed air. Conditioned air improves productivity, reduces maintenance and lowers operating costs.

The most prevalent contaminant in compressed air is water. Water, in the form of vapor, enters the air system at the compressor intake, and is concentrated to the saturation point by compression. As cooling occurs downstream of the compressor, the moisture in this saturated air condenses into harmful liquid water.

Still another contaminant, oil, is injected into air systems by lubricated compressors. Many liters of oil can enter an air system over the course of time in this way.

Airblast compressed-air conditioning equipment removes all contaminants and ensures dry and clean air.

Catalogs

Other Shandong Kaitai Shot Blasting Machinery Share Co., products

Sandblasting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.