- Packing - Handling - Logistics

- Packing and Packaging

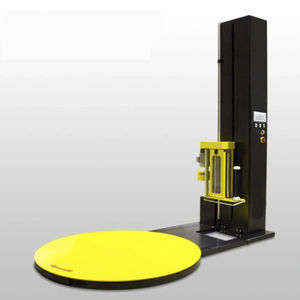

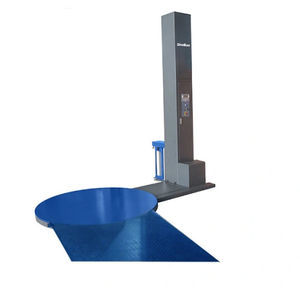

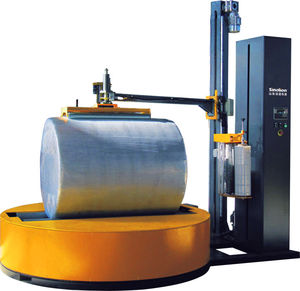

- Turntable stretch wrapper

- SHANDONG SINOLION MACHINERY CORP LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Turntable stretch wrapping machine T1650Fsemi-automaticpalletstretch film

Add to favorites

Compare this product

Characteristics

- Type

- turntable

- Operating mode

- semi-automatic

- Product applications

- pallet

- Other characteristics

- stretch film

- Machine weight

700 kg

(1,543.24 lb)- Maximum wrapping height

1,800 mm, 2,400 mm, 2,800 mm

(70.87 in, 94.49 in, 110.24 in)- Maximum pallet length

Min.: 500 mm

(19.69 in)Max.: 1,200 mm

(47.24 in)- Maximum pallet width

Min.: 500 mm

(19.69 in)Max.: 1,200 mm

(47.24 in)- Maximum pallet weight

2,000 kg

(4,409.25 lb)- Table diameter

1,650 mm

(64.96 in)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 15 rpm

(94 rad.min-1)- Voltage

220 V

- Capacity

Min.: 20 p/h

Max.: 40 p/h

Description

1. Durable using, our wrapping machines can be used for super 10 years which is approved by most of our customers.

2. Easy handling, we improve the machine according to 20 years experience to make it more human friendly, safe and easy operation.

3.The best internationally famous electrics elements, like PLC and inverter of Dema, Omron, Siemens and Schneider, etc. Schneider Contactor, etc.

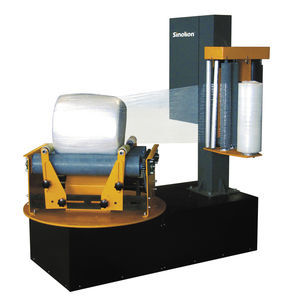

4. For the light-weight goods, the goods will be pressed and fixed by Top Platen device to guarantee the stability during wrapping.

1. Special design function sign on the display, thus the machines can be used in different countries easily.

2. The film head is at the front of the mast. It will be easy for the installation by the end users. The film head door design is to make easy for the film thread when change the film roll. And there is photo eye to sense the pallet height. Film stretching ratio is 300% for more film saving. Double chains are designed and lifting speed can be adjustable, which is of stable wrapping, high efficiency and long service life.

Controls

HMI Digital display

Photo-eye pallet height sensor

Reinforce wrap allow more wrap on same location

0-15RPM variable turntable speed by inverter

Cycle pause capability

Turntable

Go home position after wrap cycle finished.

Soft start/soft stop, Heavy duty chain drive.

Film carriage

Powered pre-stretch system: stretch ratio up to 300% to minimum film consumption (Pre-stretch ratio can be specially made)

Carriage door opens for effortless roll change and thread film

Film delivery variable speed by separate AC Drive Motor.

Heavy duty double-chain carriage lift, calm and safety.

VIDEO

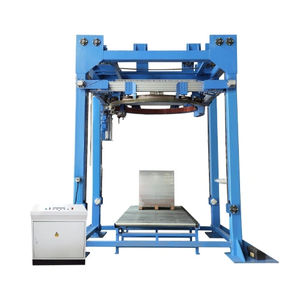

Other SHANDONG SINOLION MACHINERY CORP LTD products

Wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- SINOLION stretch wrapper

- SINOLION automatic stretch wrapper

- Packing machine for the food industry

- SINOLION stretch film stretch wrapper

- SINOLION strapping machine

- SINOLION pallet stretch wrapper

- Palletizer

- SINOLION automatic strapping machine

- SINOLION turntable stretch wrapper

- Sealer

- Automatic palletizer

- Roll foil

- Case sealer

- Medical packing machine

- Layer palletizer

- SINOLION semi-automatic stretch wrapper

- Robotic palletizer

- Adhesive tape case sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.