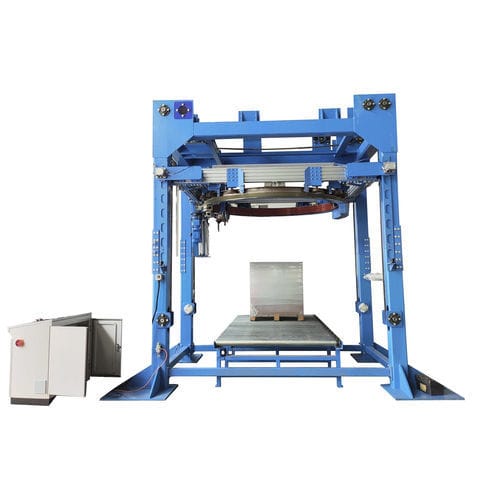

Automatic orbital ring Wrapping Machine for pallet wrapping with high efficiency.

The machine is mainly composed of:

Rotary ring drive parts

•Motor frequency control with brake;

Machine frame

•The frame is a gantry four-column square tube steel structure, the material is Q235

•The lifting part of the frame is equipped with a transmission bracket

•The rotary ring lifting unit is fixed on the frame of rotary arm by the slewing ring

Film carriage parts

•Install a height sensor on the film carriage to automatically detect the height of goods;

•AC motor for film pre-stretch, power: 0.55kw;

•The film carriage stretch ratio is 1:2.5 (150%), and the film feed speed is adjustable.

Film carriage servo mechanism

•The feeding film dance arm of the film carriage rotating, and the proximity switch controls •the start and stop of the film feed motor to achieve the follow-up of the film feed.

•Film delivery speed analog control.

Automatic feeding & cutting film device

• After the wrapping is completed, automatically cutting the film and hold the film tail

• When the film clamp releases the film head, the cutting & feeding film device automatically blows the film head and wraps it into the pallet to ensure that no film tail;

• After film cutting with wire, the wipe unit wipes film tail onto pallet for high working efficiency.

Safety protection device

• The machine frame parts have safety device and protective fence, the door lock of protective interlocks with equipment. When the safety door is opened, the equipment stops running.

• Protective fence size: L3900mm*W3640mm (subject to the drawings)