- Packing - Handling - Logistics

- Packing and Packaging

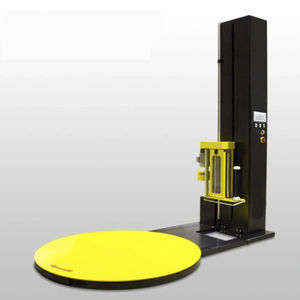

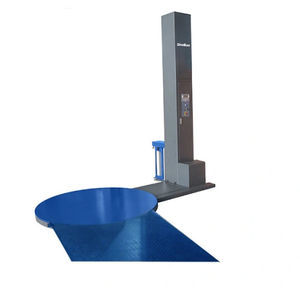

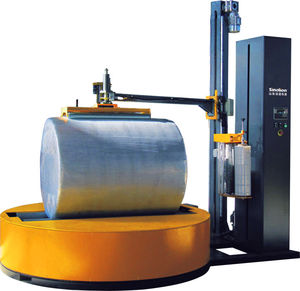

- Rotary arm stretch wrapper

- SHANDONG SINOLION MACHINERY CORP LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

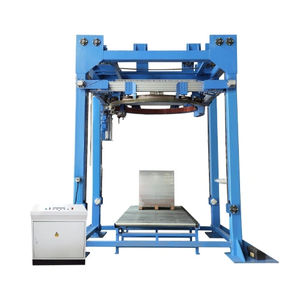

Rotary arm wrapping machine R1800FZ-PL fully-automatic

Add to favorites

Compare this product

Characteristics

- Type

- rotary arm

- Operating mode

- fully-automatic

- Height

3,220 mm

(127 in)- Width

1,800 mm

(71 in)- Length

3,440 mm

(135 in)- Machine weight

680 kg

(1,499.14 lb)- Maximum wrapping height

2,400 mm

(94.49 in)- Maximum pallet length

Min.: 500 mm

(19.69 in)Max.: 1,300 mm

(51.18 in)- Maximum pallet width

Min.: 500 mm

(19.69 in)Max.: 1,200 mm

(47.24 in)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 25 rpm

(157 rad.min-1)- Voltage

220 V, 380 V

- Power

0.37 kW, 0.55 kW, 1.1 kW, 1.5 kW

(0.5 hp, 0.75 hp, 1.5 hp, 2.04 hp)- Capacity

Min.: 30 p/h

Max.: 60 p/h

Description

1. Stable performance.

2. The Max. speed of arm rotating is 35 rpm and double rotary arms can be equipped.

3. Excellent wrapping effectiveness. Good film clamp& cuting unit with Europe technology. Nicer film sealing and cutting effect.

4. Top film sealing and cutting unit will realize best sealing effect, which is suitable for storage in 3D warehouse.

5. Top platen device will guarantee the stability of products during wrapping.

Control System

• PLC system;

• Reinforce wrap allow more wrap on same location;

• Film Tension Control adjustment in the panel;

• 0-25RPM arm variable speed by frequency changer;

• Separate variable carriage up/down speed;

• Cycle pause capability;

• Separate start, reset and emergency stop buttons;

• Manual carriage up/down switch;

• Turntable jog button;

• Flash light for machine in operation;

• Rotary arm stop by safety bumper and reflection photoeye sensing and obstacle in the rotating area;

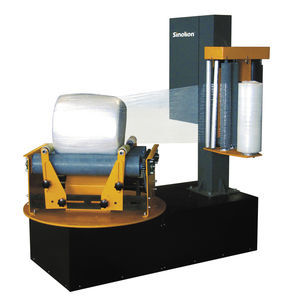

Film Carriage

• Powered pre-stretch system up to 300% to min film consumption(Prestretch ratio can be customized based on requirements);

• Film delivery variable speed by separate AC Drive Motor;

• Film dancer-bar with variable speed output;

• Rotating Power sliding ring provide power required for film carriage driven on rotary arm;

Top film cut&clamp unit

•Pneumatic clamp the film tail after wrapping;

•Hot wire film cut;

•Hot sealing and timely wind cooling;

Arm drive

•Slewing Bearing drive system;

•Soft start /stop;

Other SHANDONG SINOLION MACHINERY CORP LTD products

Wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- SINOLION stretch wrapper

- SINOLION automatic stretch wrapper

- Packing machine for the food industry

- SINOLION stretch film stretch wrapper

- SINOLION strapping machine

- SINOLION pallet stretch wrapper

- Palletizer

- SINOLION automatic strapping machine

- SINOLION turntable stretch wrapper

- Sealer

- Automatic palletizer

- Roll foil

- Case sealer

- Medical packing machine

- Layer palletizer

- SINOLION semi-automatic stretch wrapper

- Robotic palletizer

- Adhesive tape case sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.