- Packing - Handling - Logistics

- Packing and Packaging

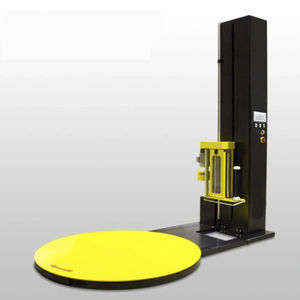

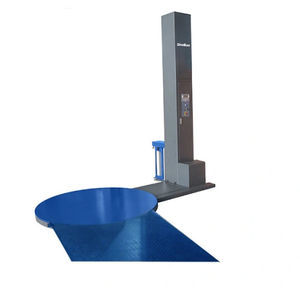

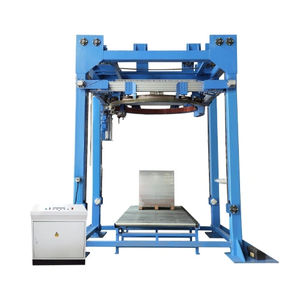

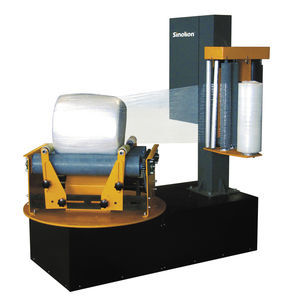

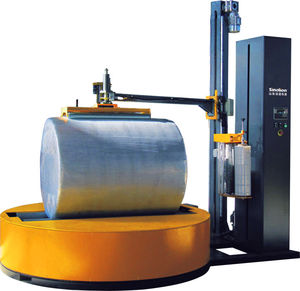

- Turntable stretch wrapper

- SHANDONG SINOLION MACHINERY CORP LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Turntable stretch wrapper T2000FZ-PL 782automaticconveyor chainfor milk

Add to favorites

Compare this product

Characteristics

- Type

- turntable

- Operating mode

- automatic

- Product applications

- pallet, carton, conveyor chain, for milk

- Other characteristics

- stretch film, open

- Maximum wrapping height

2,000 mm

(78.74 in)- Maximum pallet length

1,200 mm

(47.24 in)- Maximum pallet width

1,100 mm

(43.31 in)- Table diameter

1,800 mm

(70.87 in)- Rotational speed

Max.: 15 rpm

(94 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Voltage

380 V

Description

• Film carriage on the front of the tower

• Open-door pre-stretch standard film carriage. Powered pre-stretch film carriage 250% (1:3.5);

• Film carriage lifting driving: chain driving, good stability and high reliability

• After finishing stretch wrapping, the film will be cut and clamped automatically.

• Air blowing to wrap film head into pallet.

• Hot melt cutting wire to cut the film, and then wipe the film tail.

Control system

• Table type control cabinet with PLC and HMI

• All motors should be designed with ON/OFF switch

• 4-8 parameter settings available in PLC control system

• Auto height detection, wrapper will stop when film break/off

• Cables connected to the wrapper cabinet. Customer should prepare cable from wrapper to other system.

Catalogs

No catalogs are available for this product.

See all of SHANDONG SINOLION MACHINERY CORP LTD‘s catalogsOther SHANDONG SINOLION MACHINERY CORP LTD products

Wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- SINOLION stretch wrapper

- SINOLION automatic stretch wrapper

- Packing machine for the food industry

- SINOLION stretch film stretch wrapper

- SINOLION strapping machine

- SINOLION pallet stretch wrapper

- Palletizer

- SINOLION automatic strapping machine

- SINOLION turntable stretch wrapper

- Sealer

- Automatic palletizer

- Roll foil

- Case sealer

- Medical packing machine

- Layer palletizer

- SINOLION semi-automatic stretch wrapper

- Robotic palletizer

- Adhesive tape case sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.