- Industrial machines and equipment

- Printing, Marking and Engraving

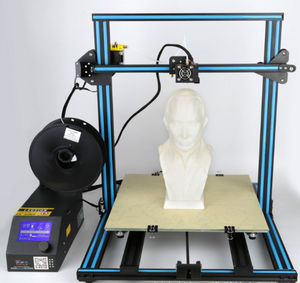

- Floor-standing printer

- Shandong Wami CNC Technology Co., Ltd.

UV inkjet printer CA-F6018floor-standingdigitalindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- UV inkjet

- Configuration

- floor-standing

- Other characteristics

- digital, industrial

- Resolution

Max.: 1,440 dpi

Min.: 1,440 dpi

Description

small 3D t-shirt printer for Leather, silk, polyester, cotton, chiffon, canvas

1, using paint ink, ink environmental protection (tested by SGS), printing fastness can reach 4, inkjet no waste (refer to where to play, computer control inkjet)

2, the operator requirements are not high, do not need to experience the old color master, film master, screen master, no need to repeat the color process, pure computer operation, only a designer, through the computer to solve the high requirements of personnel.

3. The printing machine is small in size and has a small footprint. It can be placed in an ordinary room for printing operations;

4, breaking the silk screen can not complete the transition color, gradient color printing high requirements. The computer output prints, and you want to print it.

5. It can adjust the height in the range of 0~8CM to carry out color photo-level printing on the surface of finished and semi-finished products of various costumes.

6, replace the traditional special printing (screen printing, thermal transfer, water transfer), free of intermediate consumables (such as: hot stamping paper, crystal glue, crystal film, high temperature tape, thermal transfer equipment), the overall cost savings of more than 80%.

7. The printing machine can be customized from 600mm*800mm to 1600mm*6000mm, which can meet the needs of different printing formats. The digital printing treadmill can grow indefinitely as you think, 12 meters, 24 meters, 36 meters is no longer a problem.

8. On-demand printing, no waste of ink, suitable for small-volume, multi-variety, personalized, fast-changing market demand;

Catalogs

No catalogs are available for this product.

See all of Shandong Wami CNC Technology Co., Ltd.‘s catalogsOther Shandong Wami CNC Technology Co., Ltd. products

UV flatbed printer

Related Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Printing machine

- Industrial printer

- High-speed marking machine

- Compact marking workstation

- Fiber laser marking machine

- Color label printer-applicator

- Laser engraving system

- Air-cooled marking machine

- Wood engraving machine

- Floor-standing printer

- Glass engraving machine

- Plastic engraving machine

- Metal engraving system

- Digital printing machine

- CNC engraving machine

- Computer-controlled marking machine

- Stone engraving machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.