- Hydraulics - Pneumatics

- Pump

- Centrifugal pump

- Shandong Zhangqiu Blower Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

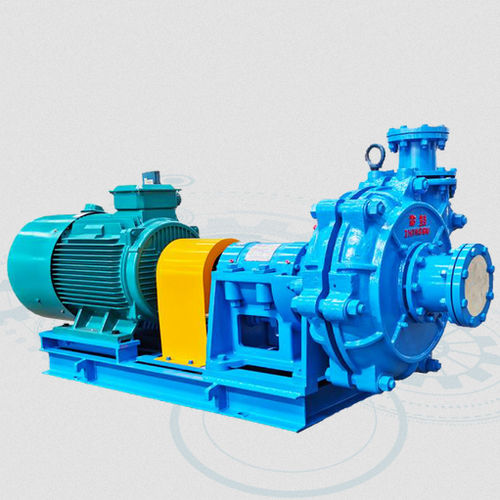

Centrifugal pump TZJKT slurryelectricstationary

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- slurry

- Operation

- electric

- Mobility

- stationary

- Domain

- industrial

- Applications

- process, transport

- Material

- ceramic, copper

- Protection level

- abrasion-resistant

- Other characteristics

- combined, non-metal

- Flow

Max.: 2,000 m³/h

(70,629.33344 ft³/h)Min.: 50 m³/h

(1,765.73334 ft³/h)- Head

Max.: 100 m

(328'01" )Min.: 10 m

(32'09" )- Fluid temperature

85 °C

(185 °F)

Description

TZJKT series ceramic slurry pump is developed based on the TZJ series slurry pump combined with the latest ceramic technology and it is awarded national invention patent.

Ceramic slurry pump has the significant wear-resisting performance compared to the metal slurry pump in metal concentrators, non-metal concentrators, smelters, etc. It has been recognized by customers since this pump entered the market.

"Wetted parts"-- wear-resistant ceramics: wear resistance, cavitation resistance, long life! The service life of ceramic flow parts is three times that of wear-resistant metal flow parts, which can really reduce cost and increase efficiency.

"Shaft seal" -- Shaft seal can choose the company's patented shaft seal technology: Expeller + mechanical seal, completely achieve zero leakage of shaft seal. Also can choose the traditional shaft seal way: Expeller + packing seal

Application:

Metal ore (gold, silver, copper, iron, plumbum, etc.) concentrator pulp feeding and all kinds of concentrate, tailings and various process material transportation;

Non-metallic ore (such as phosphate) concentrator pulp and all kinds of concentrate, tailings and transport of various process materials.

Transport of various abrasive slurry in the production of titanium dioxide, iron red powder, phosphate fertilizer and potash fertilizer.

Main feature: The wet parts are made of wear-resisting ceramic materials, whose wear resistance is more than 3 times that of high chromium wear-resisting alloy, and whose hardness is as high as Mohs hardness 9, next to diamond.

Catalogs

No catalogs are available for this product.

See all of Shandong Zhangqiu Blower Co.,Ltd‘s catalogsOther Shandong Zhangqiu Blower Co.,Ltd products

Industrial Pumps

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Vacuum generator

- Suction pump

- Vacuum pump

- Submersible pump

- Single-stage vacuum pump

- Impeller pump

- Top-mounted pump

- Vertical pump

- Lubricated vacuum generator

- Lubricated vacuum pump

- Process pump

- Slurry pump

- Effluent pump

- Cooling pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.