- Building - Construction

- Industrial Building Equipment

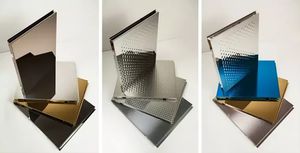

- Aluminum facing sandwich panel

- Shanghai Alubang Decorative Material Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Low-density polyethylene (LDPE) core sandwich panel aluminum facingwallcorrosion-resistant

Add to favorites

Compare this product

Characteristics

- Core

- low-density polyethylene (LDPE) core

- Facing

- aluminum facing

- Applications

- wall

- Other characteristics

- corrosion-resistant

Description

ALUBANG Normal PVDF ACP

PVDF aluminum composite panels are produced by advanced equipment with German technique. It has two layers of anti-rust aluminum sheets, formed by low density polythene (LDPE) and DUPONT adhesive polyolefin film with continuously high temperature and high press. The surface aluminum sheet has been coated with 70% PVDF (polyvinylidene fluoride). And the backside aluminum sheet has been protected with an anticorrosive primer coat.

PVDF aluminum composite panel is applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

Raw Material

Aluminum Material: High strength aluminum alloy sheet

Core Material: Non-toxic low-density polyethylene

Surface Coating: PVDF coating

Bottom Coating: Anticorrosive primer coating

Characteristic of Normal PVDF ACP

1. High Peeling Strength

ALUBANG panel is cross linking under high temperature with high performance and molecular binding materials from DuPont, which reaches the best level for the important feature high peeling strength.

2. Superior Weather Resistance

By means of KYNAR500 based PVDF coating resin, ALUBANG panel possesses superiorities in corrosion resistance, alkali resistance, chalking resistance of ultraviolet light. When exposed to the heat of tropical sunshine or the cold of frigid snowstorm, the panel never loses its colorful appearance.

3. Light Weight and Easy to Process

ALUBANG panel is easy to process for its light weight (3.7-5.7kg/m2) which can decrease the loss during an earthquake.

Other Shanghai Alubang Decorative Material Co., Ltd. products

Metal Composite Panel

Related Searches

- Sandwich panel

- Wall sandwich panel

- Aluminum facing sandwich panel

- Ceiling sandwich panel

- Fire-resistant sandwich panel

- Partition wall sandwich panel

- Facade sandwich panel

- Honeycomb sandwich panel

- Interior sandwich panel

- Sound-absorbing sandwich panel

- Floor sandwich panel

- Roof sandwich panel

- Corrosion-resistant sandwich panel

- Waterproof sandwich panel

- Weather-resistant sandwich panel

- UV-resistant sandwich panel

- Scratch resistant sandwich panel

- Cladding sandwich panel

- Laboratory sandwich panel

- Wear-resistant sandwich panel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.