- Hydraulics - Pneumatics

- Pump

- Diaphragm pump

- Shanghai Apollo Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Diaphragm pump ADY oilwith electric motorself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- diaphragm

- Fluid

- oil

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- mobile

- Domain

- industrial

- Applications

- cooling, washing, outlet

- Other characteristics

- mechanical, double, axial, ball bearing, seal

- Flow

Min.: 50 m³/h

(1,765.73334 ft³/h)Max.: 1,300 m³/h

(45,909.06674 ft³/h)- Head

Min.: 100 m

(328'01" )Max.: 1,500 m

(4921'03" )- Power

2,500 kW

(3,399.05 hp)- Fluid temperature

Min.: 0 °C

(32 °F)Max.: 85 °C

(185 °F)

Description

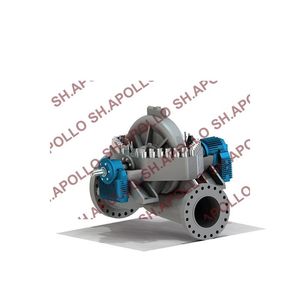

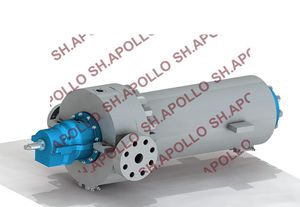

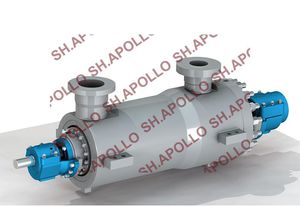

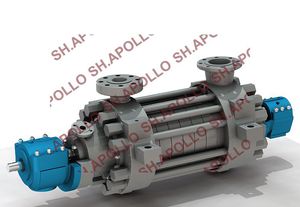

It is a multistage, horizontal split centrifugal pump with the inlet and outlet designed at two sides of the pump body and arranged horizontally;

It has a reasonable design structure and features including stable operation, low noise, convenient operation and overhaul and high efficiency; |When overhauling, the rotor part can be repaired by opening the upper casing directly without removing the inlet and outlet pipelines;

A double volute chamber is adopted in the delivery chamber with the front and rear impellers arranged symmetrically. Therefore, the radial force and the axial force are balanced in theory with the generated residual and instant axial force endured by a pair of angle contact ball bearing installed at the non-driving end;

An antifriction bearing is adopted with a cylindrical rolling bearing installed at the driving end and angle contact ball bearings in pairs designed at the free end; Using rolling bearings, driven end is cylindrical roller bearings, the free end is a pair of angular contact ball bearings, the free end is a pair of angular contact ball bearings, and air cooling is adopted;

The shaft seal is cartridge mechanical seals and PLAN11 is the adopted washing way;

The pump is driven by a motor through a diaphragm coupling; viewing from the coupling end, the pump rotates clockwise.

Other Shanghai Apollo Machinery Co., Ltd products

Engineering pump

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Stainless steel pump

- Lubricant pump

- Chemistry pump

- Suction pump

- Lubricating oil pump

- Diaphragm pump

- Mechanically-actuated pump

- Impeller pump

- Discharge pump

- Work pump

- Standard pump

- Top-mounted pump

- Vertical pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.