- Hydraulics - Pneumatics

- Pump

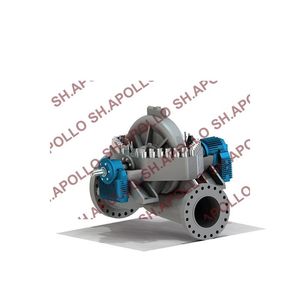

- Centrifugal pump

- Shanghai Apollo Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Centrifugal pump M310waterelectricself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water

- Operation

- electric

- Priming

- self-priming

- Mobility

- mobile

- Domain

- industrial, chemical

- Applications

- for control, lift, replacement

- Other characteristics

- mechanical, axial, seal, hydrostatic

- Flow

Max.: 160 m³/h

(5,650.34668 ft³/h)Min.: 0 m³/h

(0 ft³/h)- Head

Max.: 1,860 m

(6102'04" )Min.: 500 m

(1640'05" )- Power

710 kW

(965.33 hp)- Fluid temperature

Max.: 120 °C

(248 °F)Min.: 7 °C

(44.6 °F)

Description

The charging pump is an important constituent part of chemical and volume control system (RCV).

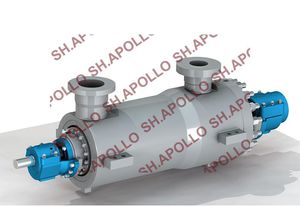

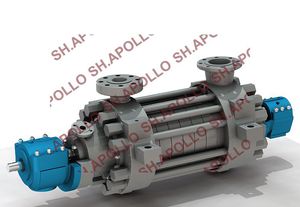

The pump is a horizontal, dual casing multistage centrifugal pump.

Symmetrically arranged impellers and sectional type symmetric volute chambers can avoid effectively the occurrence of radial force.

The impeller is designed based on anti-cavitation performance, the constant axial force which is caused by the impeller and the instantaneous axial force which are caused by startup/shutdown and load variation are supported by the double-faced Michell thrust bearing on the driving-end; the entire rotor is supported by the radial bearing on the driving-end and the hydrostatic bearing on the middle non-driving end.

An improved cartridge mechanical seal is equipped to the pump set to effectively prevent the leakage of medium.

The flow-lift curve has steep features and heat shock resistance (7°C to 120°C)

Electric I E(K3), Anti-seismic of 1A category.

In order to facilitate quick overhaul, the pump internal components are all designed as an overall core cladding structure, and all components in the pump core cladding of the same model are interchangeable.

A diaphragm coupling is adopted as the coupling with an intersegment, which can ensure replacement of mechanical seal without disassembling the motor.

With simple structure, rapid disassembly and assembly, convenience for maintenance, the design life of the pump set is greater than 60 years.

Other Shanghai Apollo Machinery Co., Ltd products

Engineering pump

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Stainless steel pump

- Lubricant pump

- Chemistry pump

- Suction pump

- Lubricating oil pump

- Diaphragm pump

- Mechanically-actuated pump

- Impeller pump

- Discharge pump

- Work pump

- Standard pump

- Top-mounted pump

- Vertical pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.