- Hydraulics - Pneumatics

- Pump

- Impeller pump

- Shanghai Apollo Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

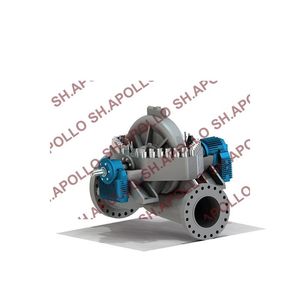

Impeller pump 2.7.9waterwith electric motorself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- impeller

- Fluid

- water

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- mobile, stationary

- Domain

- industrial

- Applications

- spray, outlet

- Material

- metal, nickel

- Other characteristics

- suction, mechanical, small, vertical, seal

- Flow

Min.: 100 m³/h

(3,531.46667 ft³/h)Max.: 1,020 m³/h

(36,020.96006 ft³/h)- Head

Min.: 92 m

(301'10" )Max.: 180 m

(590'06" )- Power

350 kW, 500 kW

(475.87 hp, 679.81 hp)- Fluid temperature

Min.: 7 °C

(44.6 °F)Max.: 120 °C

(248 °F)

Description

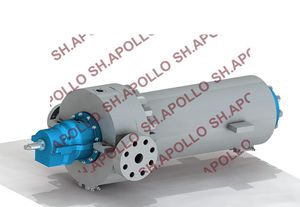

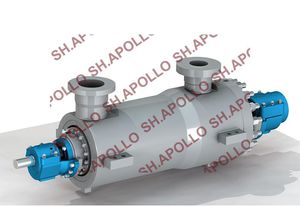

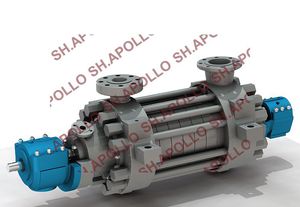

The pump is designed with a vertical barrel structure with both the pump base and pump barrel install at the same base;

The inlet and outlet of the pump are arranged at an angle of 90°at the same horizontal line;

This pump is designed with three stage impellers in total with each impeller being of single suction, impellers arranged in the same direction and inducers designed in front of the first stage impellers;

View from the suction inlet, the pump rotates clockwise;

The shaft seal is cartridge mechanical seal, and O-rings are adopted as static seal;

Metal diaphragm coupling are adopted to connect the pump to the motor; The surface overlaying of the guide bearing is nickel,chromuium,boron and silicon alloy with wear-resisting, corrosion resisting and heat resistance and so on, so it can meet the operation under transient state of startup and shutdown, cold water running, hot water running, thermal transient, small flow and running with contaminated water. Upon transient friction between the pump spindle and the guide bearing, the surface overlaying of the guide bearing plays a role of wear layers, ensuring the safety and stability of the containment spray pump set during operation.

Other Shanghai Apollo Machinery Co., Ltd products

Engineering pump

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Stainless steel pump

- Lubricant pump

- Chemistry pump

- Suction pump

- Lubricating oil pump

- Diaphragm pump

- Mechanically-actuated pump

- Impeller pump

- Discharge pump

- Work pump

- Standard pump

- Top-mounted pump

- Vertical pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.