- Hydraulics - Pneumatics

- Pump

- Impeller pump

- Shanghai Apollo Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

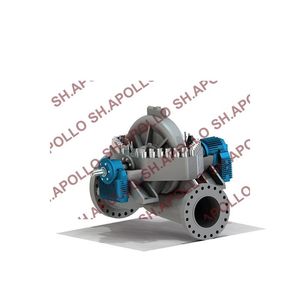

Impeller pump ALDC waterwith electric motorself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- impeller

- Fluid

- water

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- mobile, stationary

- Domain

- industrial

- Applications

- discharge, outlet

- Material

- metal

- Other characteristics

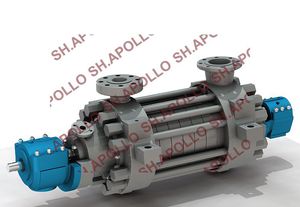

- mechanical, lubricated, double, axial, seal

- Flow

Min.: 30 m³/h

(1,059.44 ft³/h)Max.: 5,000 m³/h

(176,573.33361 ft³/h)- Head

Min.: 10 m

(32'09" )Max.: 400 m

(1312'04" )- Power

Min.: 4 kW

(5.44 hp)Max.: 710 kW

(965.33 hp)- Fluid temperature

Min.: 20 °C

(68 °F)Max.: 120 °C

(248 °F)

Description

Outlet pipe of pump can be set above or below the base according to user* s requirement. Pump installation can be divided into single foundation and double base. For single base pump, pump and motor are installed are installed on the same base, for double base pump, the pump and motor are installed on different base;

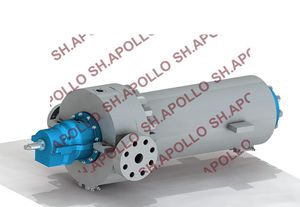

Cartridge pulling out is designed, namely after pump cover is dismantled, pump cartridge parts including the whole pump shaft components, water lubricated bearing, impeller, impeller chamber, guide vane and inner connecting pipes can be pulled out while the pump outer barrel which connects with discharge pipelines is still fixed on the pump base, which can make erection, maintenance easily;

The pump is designed of bell water inlet, band blade metal diversion cone is set in the bell inlet, which can make the pump inlet submerged depth minimized, and ensure no vortex occurs in the pump inlet;

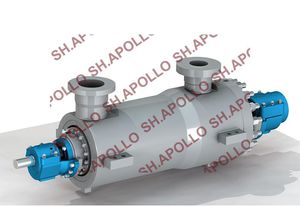

The water guide bearing is imported, at the same time, sand preventing measures are taken to prolong pump unit’s life;

The shaft seal can adopt mechanical seal or gland packing according to end-users requirement;

Pump shaft* s axial adjusting nut is set on pump body. In this case, during the installation, it* s easy to adjust the gap between impeller blades and impeller chamber without dismantling pump to ensure minimum gap value and make pump running with high efficiency.

Other Shanghai Apollo Machinery Co., Ltd products

Engineering pump

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Stainless steel pump

- Lubricant pump

- Chemistry pump

- Suction pump

- Lubricating oil pump

- Diaphragm pump

- Mechanically-actuated pump

- Impeller pump

- Discharge pump

- Work pump

- Standard pump

- Top-mounted pump

- Vertical pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.