- Packing - Handling - Logistics

- Conveying

- Powder pneumatic conveying system

- Shanghai Clirik Machinery

- Products

- Catalogs

- News & Trends

- Exhibitions

Gas pneumatic conveying system ST-LXB seriespowder

Add to favorites

Compare this product

Characteristics

- Product applications

- powder, gas

Description

Product Introduction of Pneumatic Conveying Equipment:

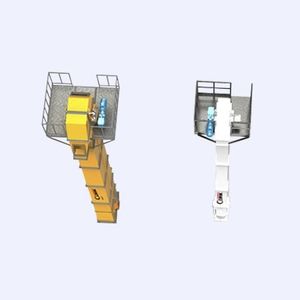

Pneumatic Conveying Equipment, which takes Roots blower as the air source, is designed specifical for close distance and continuous transporting. Transporting distances is generally horizontal distance≤ 300m, vertical distance 30m. It is suit for conveying powder specific gravity ≤1.3, fineness≥60 mesh, moisture content≤5%, under the highest instantaneous temperature≤250℃working conditions, the maximum throughput is 60 t/h. It also can be used in the nesting conditions for single-point or multi-point requirements. The equipment is with long life, low operation and maintenance costs, small size, easy controlling, widely used in mining, building materials, coal, chemical and other industries.

Working principle of Pneumatic Conveying Equipment:

Air delivery system uses the principle of gas-solid flow fluidization, jet technology, combined with differential pressure principle, to finish this working progress. Taking the electric rotary feeder as the feeding device, the material evenly is put into the mixing chamber. At the same time, the Roots blower jet the high-speed air flow of materials into the acceleration chamber, the suspended flow into the conveying pipeline transport to in silos, according the separated by the feed gas, powder fall under silo gases into atmosphere, in order to achieve a powder material handling purposes.

Benefit

1. Variable arrangement of the pipe makes the production craft process more reasonable.

2. The system is sealed and lead to few flying dust, it benefit for environment protection.

3. Few movement parts, convenient maintenance, automatic control can be realized easily.

Other Shanghai Clirik Machinery products

Feeding & Conveyor

Related Searches

- Rail conveyor

- Conveying belt

- Conveyor for the food industry

- Feeder

- Drag chain conveyor

- Food conveyor

- Bulk products conveyor

- Screw conveyor

- Feeding conveyor

- Vertical rail conveyor

- Vibrating feeder

- Pneumatic conveying system

- Construction conveyor

- Conveyor for the mining industry

- Powder conveyor

- Powder pneumatic conveying system

- Industry feeder

- Heat-resistant conveyor belt

- Elevator bucket

- Linear feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.