- Packing - Handling - Logistics

- Conveying

- Plate conveyor belt

- Shanghai Clirik Machinery

- Products

- Catalogs

- News & Trends

- Exhibitions

Plate conveyor belt TD seriescementhinged beltpowder

Add to favorites

Compare this product

Characteristics

- Type

- plate

- Material

- cement

- Pattern

- hinged belt

- Applications

- powder

- Tolerance

- heat-resistant

Description

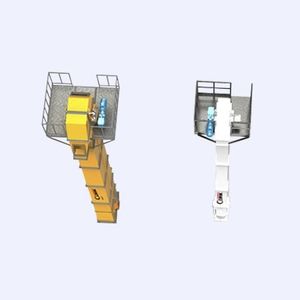

TD series belt elevator is the related equipment of Grinder Mills, also known as a kind of bucket-type elevator. TD series belt elevator is suitable to lift powder, granular, and bulk materials with small grinding suction, such as grain, coal, cement, crushed ore, up to 40m. The common models of TD series belt elevator are TD100, TD160, TD250, TD315, TD400, TD500, TD630, TD800, TD1000, etc. Among them, TD160, TD250, TD315 are the most common types. Shanghai Clirik TD series belt elevator is available in four kinds of hopper

TD series belt elevator, according to its hopper’s speed, can be divided into: centrifugal discharge, gravity discharge and hybrid discharge. Centrifugal discharge, with high-speed hopper, is suitable for conveying powder, granular, small block, and abrasive materials. Gravity discharge, with slow-speed hopper, is suitable for conveying the block, materials with a large size and abrasive, such as limestone, clinker. Traction component of the bucket elevator includes chain, plate chain and tape. The structure and manufacturing of the chain is relatively simple but heavy, also in strong connection with the hopper, suitable for conveying of abrasive materials. Plate chain, with strong and light structure, is suitable for lifting heavy hoist, but hinged joints susceptible to wear. The structure of the tape is relatively simple, but not suitable for conveying abrasive materials .The temperature of material to be conveyed should be lower than 60 ° C for ordinary tape, 80 ° C for steel-rope tape, 120 ° C for heat-resistant tape, and 250 ° C for chain , plate chain.

Other Shanghai Clirik Machinery products

Feeding & Conveyor

Related Searches

- Rail conveyor

- Conveying belt

- Conveyor for the food industry

- Feeder

- Drag chain conveyor

- Food conveyor

- Bulk products conveyor

- Screw conveyor

- Feeding conveyor

- Vertical rail conveyor

- Vibrating feeder

- Pneumatic conveying system

- Construction conveyor

- Conveyor for the mining industry

- Powder conveyor

- Powder pneumatic conveying system

- Industry feeder

- Heat-resistant conveyor belt

- Elevator bucket

- Linear feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.