The structure is simple and reasonable, and the raised movable jaw tooth plate has a good protective effect on the movable jaw and the bearing chamber, and also ensures the unobstructed feeding and avoids the phenomenon of jamming, which is safe and reliable.

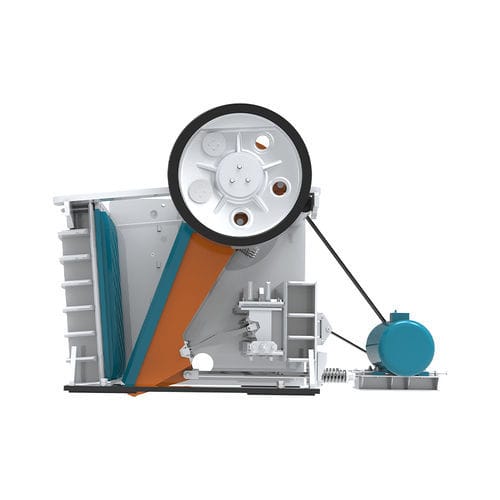

Most of the stones used in engineering are hard rocks such as basalt, and the hardness of the material is relatively high. The traditional jaw crusher not only has low output but also is easy to wear. Compared with the traditional jaw crusher, the PEW European version jaw crusher shows its unparalleled superiority in terms of service life, maintenance rate and failure rate. That said, the cost is still low.

Advanced craftsmanship high-end materials

Using advanced manufacturing technology and high-end production materials. The use of finite analysis techniques makes the machine stronger. The crushing cavity adopts a symmetrical "V" shape structure, so that the actual feeding port width is consistent with the nominal feeding port width.

Enhanced radial strength.

The movable jaw assembly is made of high-quality steel castings, and the heavy-duty eccentric shaft is machined from forged billets, making the machine extremely reliable and durable. The bearing seat adopts an integral cast steel structure to ensure complete cooperation with the crushing frame, which greatly enhances the radial strength of the bearing seat.

Adjustment device

Equipped with a wedge discharge opening adjustment device, which is simpler, safer and faster than the old-fashioned shim adjustment. The latest tooth-shaped guard plate is adopted to increase the effective length of the jaw plate and increase the output.