- Packing - Handling - Logistics

- Packing and Packaging

- Horizontal stretch wrapper

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Horizontal wrapping machine automaticprofilestretch film

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Operating mode

- automatic

- Product applications

- profile

- Other characteristics

- stretch film, with strapping function

Description

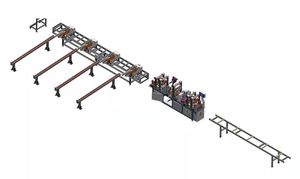

This machine is more like a Advanced equipment for profile wrapping. It could be used for wrapping with paper and entensive film, but tapping is another flash point of it. The tapping process starts while is profile moving and wrapping. The whole movement is automatic controlled by the system.

SUB-BUNLE STRAPPING MACHINE WITH TRANSFER BELT

Three to four wrapping station perform the strapping process, profile bundles are loaded to the platform by workers. Automatic positioning before strapping. The lifter load the bundles one by one after strapping is down.The ring rotates and holds the roll of wrapping film which is supported by a mandrel with specially clutch designed to maintain the tension constant until the roll is finished. The speed is regulated by means of an electronic inverter. An automatic device senses when the roll has run out or wrapping material tears, bringing the machine to a complete stop and warning the operator. Machine designed to operate in “start and stop” mode with a blade cutting the wrapping material at the end of the each wrapping cycle. Times can be set according to your needs.

The front reinforced transfer belts are designed to transport the Sub-Bundles to the in-feed Roller Table of Sub-bundle wrapping machine. The belt deposits the packs solely if the roller table is occupied.

Powered roller table is for the transportation of the profiles in and out of the sub-bundle wrapping machine. The in-feed roller table is outfitted with centering rollers to maintain the profiles centered on the roller table prior to entering the wrapping machine. Spiral wrapping machine designed to wrap sub-bundles using 25 micron thick of stretch film.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Aluminum profile packing line

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Automatic strapping machine

- Bagging machine for the food industry

- Shrink wrapper

- Film packing machine

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Horizontal bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.