- Packing - Handling - Logistics

- Packing and Packaging

- Horizontal stretch wrapper

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

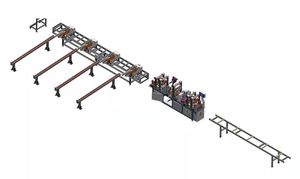

Horizontal wrapping machine fully-automaticfor aluminum profileswith conveyor

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Operating mode

- fully-automatic

- Product applications

- for aluminum profiles

- Other characteristics

- with conveyor

Description

Machine is designed with a compact steel frame. Replacement of wrapping material is carried out quickly and easily. Profiles are drawn through the machine by a series of rollers which open and close automatically, allowing bundles with different dimensions to pass through automatically without stopping the machine.

Powered roller table is for the transport of the profiles in and out of the sub-bundle wrapping machine. The infeed roller table is outfitted with centering rollers to maintain the profiles centered on the roller table prior to entering the wrapping machine. Spiral wrapping machine designed to wrap sub-bundles using 25 micron thick of stretch film. The wrapping operation is fully automatic. The sections are fed into the machine. The ring starts automatically. Once the ring has done two or more turns, the transfer rollers transport the profiles until the wrapping operation is finished. At this point a mechanical hand holds and cuts the wrapping material, allowing for the exit of the profile. Material draw-back device ensures constant tension of wrapping material. The conveyor will protect your profile surface from damages. The entire operation is automatic.

Aluminum profile packing line with timber feeding

This automatic feeding machine can automatic feeding the timber block to the top and bottom of the aluminum bundle. The action step controlled and detected by PLC. It adopts photo electricity for inducing the product. The top timber feeding height of machine can be adjusted per product height. This feeding station can connect to wrapping station which can be move in and out to facilitate your packing needs.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Aluminum profile packing line

Related Searches

- Packing machine

- Automatic packing machine

- Bagging machine

- Wrapping machine

- Automatic bagging machine

- Packing machine for the food industry

- Automatic wrapping machine

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Bagging machine for the food industry

- Automatic strapping machine

- Shrink wrapper

- Film packing machine

- Horizontal bagging machine

- Automatic shrink wrapper

- Turntable wrapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.