- Packing - Handling - Logistics

- Packing and Packaging

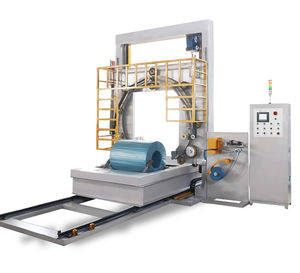

- Turntable stretch wrapper

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Horizontal wrapping machine FPCA-1000rotary ringturntableautomatic

Add to favorites

Compare this product

Characteristics

- Type

- horizontal, rotary ring, turntable

- Operating mode

- automatic

- Product applications

- for profiles, for coiled tubing, for corrugated pipes, for PE pipes, for the steel industry, for aluminum coil, for copper coils, for steel coils, for pipes, for hoses

- Other characteristics

- stretch film, with conveyor, with motorized roller conveyor, with free roller conveyor, high-speed

Description

Automatic wrapping station

• Both Manual and Auto working modes can be choose for flexible operation.

• PLC & HMI are adopted for fully automatic operation after input coil OD/ID/Width/Overlap degree.

• Supportive rollers lifting the coil from conveyor for wrapping.

• Manual positioning makes the coil stopped at the specific positions for wrapping.

• Automatic supportive rollers.

• Wrap tension can be adjusted as need.

• The converter is adopted to adjust the packing speed according to requirement.

• Different wrapping requirements can be achieved by setting the corresponding parameters on HMI.

• Guardrails, soft starts and stop for safety operation.

• Supportive roller guiding the coil in rotation for wrapping protection.

• Stainless steel rollers on conveyor are durable & anti-rusted.

• Height of conveyor/work table is adjustable.

• Cutting the packing tape automatically by program according to different coils.

• Packing tape clamp & cut by automatic mechanical hand automatically.

• Independent & convenient control panel positioned for whole wrapping control.

• Friction between ring and wheels is adjustable.

• Indicator alarms automatically when trouble occurs. Trouble can be shown automatically.

• Conveyor length can be made according to need.

• Automatic mechanical hand for packing material clamping & cutting.

• Soft start and stop operation

• Automatic mechanical handing of packing material clamping&cutting.

• Height of conveyor table adjustable 880-890mm

• Work table total width 1200mm (net 1100mm inside between 2 channel width 50mm)control panel should be touched and controlled atthe operator side over the machine

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Steel coil wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Automatic strapping machine

- Bagging machine for the food industry

- Shrink wrapper

- Film packing machine

- Automatic shrink wrapper

- Turntable wrapping machine

- Horizontal bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.