- Packing - Handling - Logistics

- Packing and Packaging

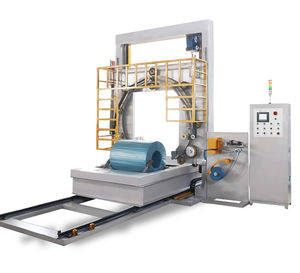

- Rotary ring stretch wrapper

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary ring wrapping machine FPS-600automaticfor wire coilsstretch film

Add to favorites

Compare this product

Characteristics

- Type

- rotary ring

- Operating mode

- automatic

- Product applications

- for wire coils

- Other characteristics

- stretch film

- Width

Max.: 600 mm

(24 in)Min.: 200 mm

(8 in)- Rotational speed

Max.: 60 rpm

(377 rad.min-1)Min.: 20 rpm

(126 rad.min-1)

Description

1) Excellent collections. High quality brands are adopted for main components.

2) PLC is adopted.

3) Trolley adopted for loading& unloading of the coils conveniently, safe and reliable.

4) Height of the ring board could be adjusted by motor according to different coil OD.

5) Two different wrapping material rolls are available for wrapping at one time.

6) Wrapping film tension can be adjusted by special tension control system to achieve the good wrapping effect for all the size of coils.

7) Protective guard of ring part for safe operation.

8) The overlap of the packing tape can be adjusted by converters according to needs.

9) Soft start and soft stop functions for safe operation.

10) Packing position reset function.

11) Overloading protection.

12) Both electric limitation and mechanical limitation for operation.

13) Guardrail for the running part ensures safe operation.

14) Ring speed and roller speed are adjustable by converter.

15) Independent electrical control cabinet for easy operation and maintenance. Indicator alarms automatically when trouble occurs.

16) Friction between wheel and ring is adjustable.

17) PU wheel for long life using.

18) Packaging time can be set on the control panel for automatic stop.

19) Reinforce ring and structure, firm and stable, long life work.

Option parts:

a. Special film tension control system

Providing consistent packing tension for small and big wire coil for tighten packaging.

b. Automatic material cutter

Automatic material feeding and cutting to avoid manually job in material tie on coil and cutting.

It is a special cutter which working for cutting the stretch film&paper together.

c. Interlock

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Steel coil wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Automatic strapping machine

- Bagging machine for the food industry

- Shrink wrapper

- Film packing machine

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Horizontal bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.