- Packing - Handling - Logistics

- Packing and Packaging

- Automatic packaging line

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Pipe packaging line automatic

Add to favorites

Compare this product

Characteristics

- Product applications

- for pipes

- Other characteristics

- automatic

Description

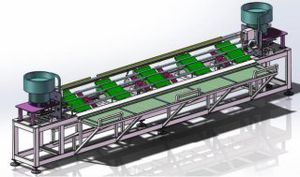

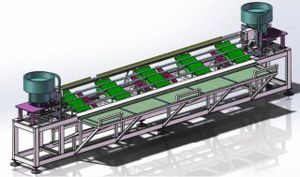

This pipe bundling machine is an automatic pipe packing line, including pipe counting, feeding, storage, aligning, bundling, strapping, conveying, etc.

It is a set of efficient, convenient and safe wrapping machinery for pipe bundle packaging. It can greatly improve the work efficiency with small labor cost.

IV. PROCESS FLOW:

1, Pipe in feeding from extruder

2, Counting the number of the pipes by program

3, Storage the pipe

4, Accumulate and array the pipes

5, Aligning the pipe bundle

6, Bundling & strapping the pipe bundle by stretch film

7, Strapped pipe bundle shift to bagging station

8, Automatic baggine and package out-feeding

1. Storage & Feeding system

It is for pipe storage to ensure uninterrupted working. The pipe lifter is for lifting the orderly pipe from basket and counting for bundling preparation.

Features:

Controlled by PLC program.

Both online and offline bundling

Pipe accumulation and storage station.

Pipe lifter for lifting the pipes.

Pipe counting device.

Defective recycle storage device.

Sensor for positioning and detecting.

Precise pipe counting system.

Buffer zone for more pipe feeding.

Pipe lifting one by one automatically.

Three position strapping

Bag size: Ø250 mm at full open

Machine size: app. L7000xW2000xH1400mm

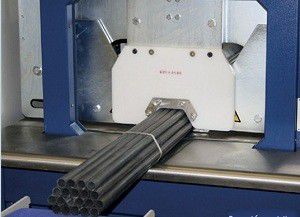

2. Film strapping machine

Automatic pipes accumulating, aligning, stringing, bundling, strapping system.

Features:

One strapping head for three place strapping.

PLC&HMI program control for automatic operation.

Pipe aligning device for keeping the orderly ends.

Pieces of pipe per bundle are changeable.

Ring speed and roller speed are adjustable by convertor.

Both manual and automatic working mode can be chose.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Plastic Pipe Packing Line

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Automatic strapping machine

- Bagging machine for the food industry

- Shrink wrapper

- Film packing machine

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Horizontal bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.