- Packing - Handling - Logistics

- Packing and Packaging

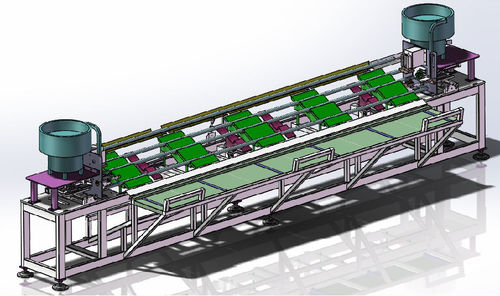

- Automatic packaging machine

- Shanghai Fhope machinery co.,ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic packing machine for pipefor tubes

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for pipe, for tubes

Description

Originality:

Current industry status:The capping machine has high requirements on the geometric shape of the pipe cap, the cap can not have flash, and the failure rate of the cap is generally 1-5%.

After many research and development tests, the industry's first opening and closing cap tooling was developed, which completely solved the failure of cap and the high requirements for cap.

QMGM capping machine has no special requirements for cap.

The failure rate is less than 0.002%.

This innovation is applying for a national patent.

Introduction:

In recent years, the labor cost has been rising continuously, and enterprises urgently need to upgrade the automation level to cope with the increasing cost pressure. Therefore, Shanghai Fhope Machinery Co., Ltd. has developed a full-automatic pipe capping machine after a year's efforts.

The machine has perfect self-checking function, highly reliable process and extremely low failure rate of cap.

The production process needs no human monitoring and is highly automated.

Compatible with multiple specifications (20,25,32), easy to change specifications.

Compatible with two length specifications (3m, 4m)

There is no requirement for the pipe cap.

Operational Environment:

Environment: indoor, no dust.

Mode: On-line, directly placed in the original turning rack.

Power supply: AC220V 50Hz.

Power: less than 1.5KW.

Compressed air: more than 0.5MPa

Gas consumption: 200cm³/ time.

Catalogs

No catalogs are available for this product.

See all of Shanghai Fhope machinery co.,ltd‘s catalogsOther Shanghai Fhope machinery co.,ltd products

Automatic Steel Tube Packing Line

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Bulk material bagging machine

- Automatic strapping machine

- Bagging machine for the food industry

- Shrink wrapper

- Film packing machine

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Horizontal bagging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.