- Metrology - Laboratory

- Laboratory Equipment

- Metallographic microscope

- Shanghai Hualong Test Instruments Corporation

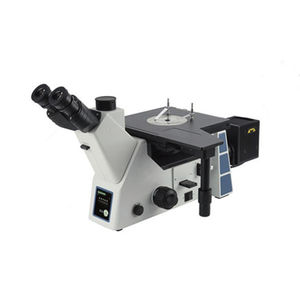

Metallographic microscope HL102-BWlaboratoryinspectioneducational

Add to favorites

Compare this product

Characteristics

- Type

- metallographic

- Technical applications

- laboratory, inspection, educational, measuring, industrial, metallurgical, for quality control, for materials research

- Ergonomics

- inverted

- Microscope head

- binocular

- Quality of the objectives

- achromatic

- Observation technique

- bright field, polarized

- Configuration

- benchtop

- Light source

- with coaxial illumination

- Options and accessories

- computer-assisted, USB, motorized, USB camera

- Other characteristics

- digital camera

Description

1. Application

The HL102-BW triocular inverted metallographic microscope adopts the excellent infinite optical system and modular functional design concept, which can easily upgrade the system and realize polarizing observation and other functions. The compact and stable high rigidity body fully embodies the vibration control requirements of the microscope operation. The ideal design meets the requirements of ergonomics, so that the operation is more convenient and comfortable, and the space is broader. It is suitable for microscopic observation of metallographic structure and surface morphology, and is an ideal instrument for metallographic, mineralogy and precision engineering research.

2. Specification

2.1 Eyepiece: Wide field WF10X (visual field number Φ22mm)

2.2 Objective lens:

PL L10X/0.25 Working distance: 20.2 mm

PL L20X/0.40 Working distance: 8.80 mm

PL L50X/0.70 Working distance: 3.68 mm

PL L100X/0.85(Dry) Working distance: 0.40 mm

2.3 Eyepiece tube: 45°tilt, IPD adjustment range 53~75mm

2.4 Focusing mechanism: Coaxial coarse focus,With locking device,Micro-grid value:2μm

2.5 Converters: Five holes (Backward ball bearing inner locating)

2.6 Stage:

Mechanical moving stage, Dimensions:242mmX200mm,

Moving Range:30mmX30mm

Circular rotating stage plate size: The largest diameter Ф130mm,

Minimum clear aperture less than Ф12mm

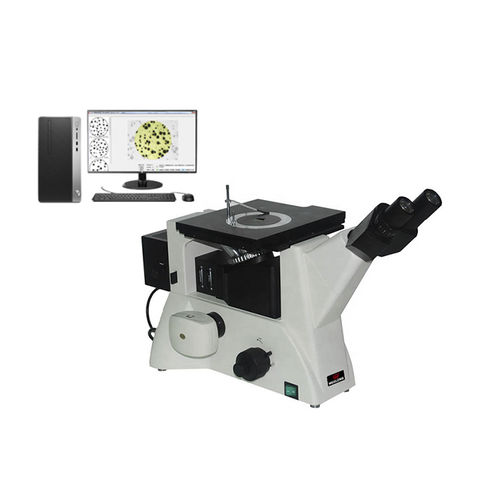

2.7 Metallographic analysis software:

Metallographic automatic analysis system JX2015 version

3 megapixel Atlas camera

0.5 X adaptation

Micromeasuring ruler

Catalogs

No catalogs are available for this product.

See all of Shanghai Hualong Test Instruments Corporation‘s catalogsOther Shanghai Hualong Test Instruments Corporation products

Microscope

Related Searches

- Cutting system

- Metal cutting system

- Automatic cutting system

- Blade cutting system

- High-speed cutting system

- Microscope

- Optical microscope

- Laboratory microscope

- Rotary blade cut-off machine

- Inspection microscope

- Cutting system with water cooling

- Tabletop microscope

- LED illumination microscope

- Digital camera microscope

- Measuring microscope

- Polarization microscope

- Analysis microscope

- Laboratory cutting machine

- Trinocular microscope

- USB microscope

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.