- Hydraulics - Pneumatics

- Pump

- Centrifugal pump

- Shanghai Kaiyuan Pump Industrial Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

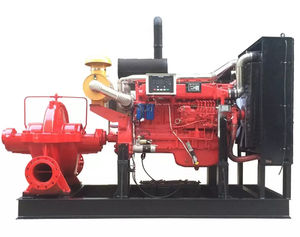

Centrifugal pump XBCwateroilfuel

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water, oil, fuel

- Operation

- diesel engine

- Mobility

- stationary

- Domain

- industrial

- Applications

- irrigation

- Other characteristics

- large, flow

- Flow

Max.: 2,000 m³/h

(70,629.33344 ft³/h)Min.: 18 m³/h

(635.664 ft³/h)- Pressure

Max.: 2 MPa

Min.: 0.3 MPa

- Head

Max.: 500 m

(1640'05" )Min.: 20 m

(65'07" )- Power

Max.: 4,500 kW

(6,118.3 hp)Min.: 20 kW

(27.19 hp)- Fluid temperature

80 °C

(176 °F)

Description

Diesel engine centrifugal pumps are commonly used in various applications where large volumes of liquids need to be moved or pressurized. They are commonly used in water supply systems, irrigation systems, agricultural applications, industrial processes, and more.

The diesel engine controller functions as the brains of the entire system. It controls and monitors the operation of the diesel engine and the pump. The controller is equipped with various sensors and relays that monitor parameters such as engine speed, oil pressure, water temperature, and fuel level. Based on these parameters, the controller adjusts the engine speed and other variables to optimize the performance of the pump. It also provides necessary information to operators, such as pump flow rate, pressure, and other relevant data. The controller can be manually operated or programmed to automatically adjust engine speed and other variables based on pre-set conditions.

Other Shanghai Kaiyuan Pump Industrial Co., Ltd. products

Centrifugal Pump

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.