- Hydraulics - Pneumatics

- Pump

- Centrifugal pump

- Shanghai Kaiyuan Pump Industrial Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

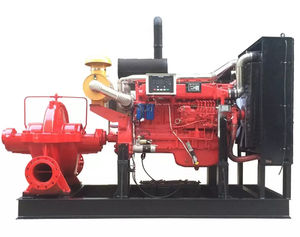

Centrifugal pump waterairdiesel

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water, air

- Operation

- diesel

- Mobility

- stationary

- Domain

- industrial

- Applications

- work, for control, spray, control

- Other characteristics

- automatic, open

Description

Automatic fire extinguishing system usually consists of automatic control cabinet, electric pump and the diesel pump. Normal pipeline pressure is between p1 to p2. When the pressure is lower than p1, the jockey pump starts to work until the pressure rises back to p2. Pressure p2 slowly drops to pressure p1 due to the pipe loss, so jockey pump starts to work again. Therefore, pressure maintains between p1 to p2. Water consumption increases when there is a fire alarm. In this case, the jockey pump can not keep the pressure higher than p1, and it will drop to p0 soon. The control cabinet gets the p0 signal or the remote start signal, it will start the electric pump. If the electric pump breaks down, the backup diesel pump will start to work and speed up in the control of the control cabinet. At the same time, the control cabinet monitors all kinds of signals and prepares to protect. As a result, the fire is put out automatically.

2. Installation environment

a) Control cabinet must be installed indoors.

b) Altitude ≤ 1000 meters.

c) Normal ambient temperature.

d) Relative humidity of the air should be 10% to 90% RH.

e) Installation inclination ≤ 5 degrees.

f) No corrosive gas and conductive dust.

g) No severe vibration.

3. Structure

Open the cabinet from the front door. Spray technology is adopted for the cabinet shell. It is painted gray or according to customers’ needs.

Other Shanghai Kaiyuan Pump Industrial Co., Ltd. products

Centrifugal Pump

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.