- Industrial machines and equipment

- Heat Exchanger and Refrigeration

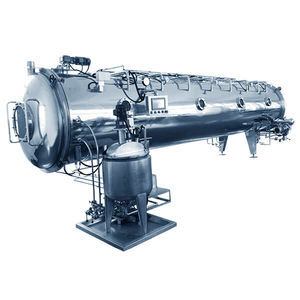

- Vacuum evaporator

- Shanghai Minjie Machinery Co.,Ltd

Vacuum evaporator MJ-NS seriesprocessfruit juiceacid

Add to favorites

Compare this product

Characteristics

- Type

- vacuum

- Laboratory/process

- process

- Applications

- fruit juice, acid

- Other characteristics

- automatic, low temperature

- Electrical output

Max.: 11,000 W

Min.: 3,900 W

Description

Vacuum low temperature evaporator is new concentrating equipment developed by our company. It realizes low temperature evaporation through high vacuum degree. There is a spinning roller inside the evaporator. Hot water is used to heat the bottom of the evaporator and the spinning roller. Continuous spinning of the roller increases evaporation area and speed, resulting in thin film evaporation. By continuous contact with the surface of the spinning roller, the raw thin material is heated to evaporate.

From feed to discharge, the whole concentration process is continuous under vacuum state. Vacuum low temperature evaporator conquers many problems met by traditional evaporator, such as, high concentrating temperature, long concentrating time, denaturation of raw material, easy scale formation during concentration, poor fluidity after concentration and no further concentration. Because of the low evaporation temperature in our equipment, active ingredients of the raw material are kept.

Range of application:

1. Fruit juice - 2. Milk Products - 3. Instant coffee and instant tea - 4. Chinese Traditional Medicine

5. Fermentation Broth - 6. Lactic acid bacteria - 7. Protease - 8. Plant extract

9. Biological products

Advantage:

▪ Continuous feed in and discharge under vacuum state

▪ Automatic, continuous, closed process

▪ Protection of active ingredients of raw material under low temperature

▪ Adjustable concentration temperature (20-50°C)

▪ No limitation of density, as long as with fluidity

▪ Online density monitor, automatic discharge of finished material

▪ CIP system: quick & thorough cleaning, no dead corner

▪ Solvents recycling

▪ GMP Standards

VIDEO

Catalogs

No catalogs are available for this product.

See all of Shanghai Minjie Machinery Co.,Ltd‘s catalogsOther Shanghai Minjie Machinery Co.,Ltd products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.