- Industrial machines and equipment

- Furnace and Heat Treatments

- Radiation dryer

- Shanghai Minjie Machinery Co.,Ltd

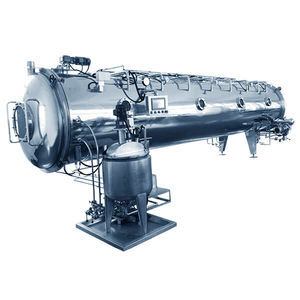

Radiation drying system MJBCD serieslow temperature

Add to favorites

Compare this product

Characteristics

- Technology

- radiation

- Other characteristics

- low temperature

Description

Thin-layer drying system is a new-style low temperature drying equipment which developed by Shanghai Minjie. It adopts low temperature radiation & thin layer drying technology which is called “the fourth generation drying technology” by international drying academic world. Equipment has “high efficiency, high quality, low energy consumption” features.

Thin-layer drying system consist of feed and distributing system, heating and drying system, low temperature air exhausting system, cooling system and discharging system, and the composition principle is shown in the figure.

Thin-layer drying system use recycled heat fluid medium as heating source. Wet material is distributed on the conveyor film, form a thin layer of material. The conveyor film run at a set speed and keep in close fit with the heating liquid. By radiation, the thermal energy of the heating medium is transferred into the wet material through conveyor film, and water of the wet material is heated and evaporated.

During the drying, material’s moisture content is gradually reduced till to the end of drying. At the end of the conveyor film, material be cooled though low temperature water. It helps material be removed from the conveyor film and it can reduce temperature’s affect to product’s quality. By controlling the running speed of the conveyor film, the drying time can be adjusted.

Thin-layer drying system, usually use hot fluid as heating medium (usually water), hot fluid surface be covered with the conveyor film which are made of a special material with poor heat conduction. So, circulating water’s thermal energy loss is limited.

Catalogs

No catalogs are available for this product.

See all of Shanghai Minjie Machinery Co.,Ltd‘s catalogsOther Shanghai Minjie Machinery Co.,Ltd products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.