- Packing - Handling - Logistics

- Packing and Packaging

- Automatic filling machine

- shanghai only packaging

- Products

- Catalogs

- News & Trends

- Exhibitions

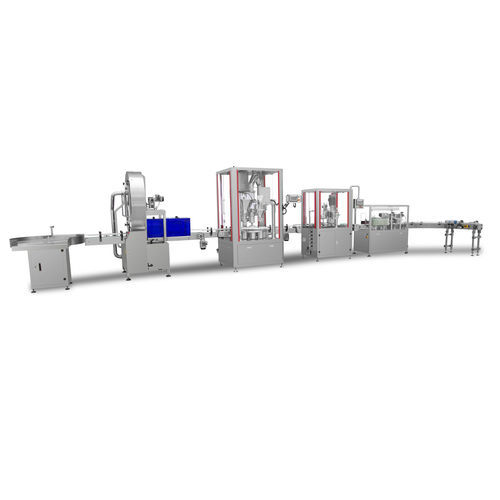

Automatic filling line canfor foodfor powders

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- can

- Product applications

- for food, for powders

- Domain

- for the food industry, medical

- Type

- weight, online, sterile, vacuum

- Number of heads

- with 2 heads

- Throughput

Min.: 12 p/min

Max.: 48 p/min

Description

Automatic canning, empty canning purging and sterilization, double-head online weighing filling, automatic vacuum filling and nitrogen sealing canning packaging line

This system is suitable for filling milk powder, protein powder and other nutrition powder into iron tin cans, and it needs to be vacuumized and filled with nitrogen to seal the cans. It is a complete assembly line equipment.

Packaging materials: special medical food, milk powder, protein powder, other nutrition powder

Applicable weight: 100-1000 grams

Tank size: #300, #307, #401, #502 cans. Tank height: 60-200mm

Production capacity: 12-48 cans/min. The speed mainly depends on the number of machines for vacuumizing and filling nitrogen sealing cans. If 3 double-head sealing machines are equipped, the speed is 36 cans/min

Single double-head can sealing machine speed: 12-14 cans/min

Filling accuracy: ±1-1.5 g

Residual oxygen: ≤3%

Power supply: 3-phase 380V 50Hz

Whole line power: 48.33

Compressed air: 1.45m3/min, pressure: 6kg/cm2

Nitrogen: purity >99.99%, pressure: 0.4mpa; ≈10 m3 / h. The demand for 3 sets is 30 m3 / h

Iron listening canning production line: automatic unloading, cleaning, empty canning purging and sterilization, double-head weighing and filling, automatic distribution of canning, automatic vacuum filling and nitrogen sealing, automatic body cleaning (removing static electricity and dust), automatic coding, automatic turning of canning, automatic pressing of canning cover, manual or automatic packing, etc.;

Other shanghai only packaging products

Automatic mixed packaging production line

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Feeder

- Packing machine for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Vacuum packing machine

- Film packing machine

- Filler for the chemical industry

- Food packing machine

- Multi-head filler

- Automated feeder

- Sealer

- Labeling machine for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.