- Packing - Handling - Logistics

- Packing and Packaging

- Screw-on screw capping machine

- Shanghai Paixie Packing Machinery Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

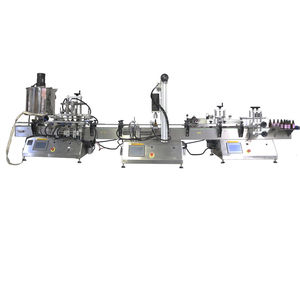

Screw-on screw capping machine PX-CP50in-lineautomaticfor bottles

Add to favorites

Compare this product

Characteristics

- Type

- screw-on, in-line

- Operating mode

- automatic

- Product applications

- for bottles, jar, for plastic bottles

- Other characteristics

- tracking

- Throughput

Max.: 80 p/min

Min.: 0 p/min

Description

The latest tracking capping machine,no damage to the cap, fast speed, safety and stability, high capping efficiency. The machine is controlled by PLC and several servo motors control the movement of the capping pro. In the process of capping, the bottle moves continuously, the capping torque is adjustable, the production speed is fast, the work is stable, the cap will not be damaged in the process of capping. This machine adopts PLC control, rocker touch screen operation, easy to use, wide range of application.Easy to adjust when changing bottle shape. The machine has the function of parameter formula saving, one button can switch the parameters of various bottle types, the servo motor automatically adjusts to the specified position. Portable capping head design,easy to replace the capping heads, by adjusting the two sides of the bottle clamping belt, can be put into the production of new products.The machine has beautiful appearance and conforms to GMP standard.

Capping Heads

1.Control capping position and torque

2.pick and place capping,high success rate cap loading

3.Servo motor control

Servo Motor

1.Control left and right tracking

Cap vibrator

Cap vibrator is also an automatic assembling equipment for capping process line, which can assort the caps in a series for an automated line with high speed. It is combined with automatic capping machine to feed the caps to the bottle automatically.

Our Advantages

We'll change into your standard plug before shipping,such as American plug, UK plug, European plug...

Catalogs

No catalogs are available for this product.

See all of Shanghai Paixie Packing Machinery Co., Ltd.‘s catalogsOther Shanghai Paixie Packing Machinery Co., Ltd. products

Capper

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.